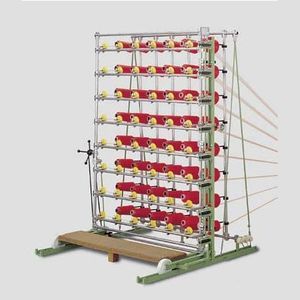

Warping machine MW series

Add to favorites

Compare this product

Description

■ Very high motor torque and thread tension

■ Extremely high motor running torque even in the case of large beam diameters

■ High-precision, synchronisation during constant running, start-up and braking

■ Very short stopping times in the case of thread breakages (prevents broken thread ends from running onto the warp beam) as a result of the switching of the drive motors to generative operation and thus the use of all the kinetic energy as braking power

■ Siemens S7 control system

■ Powered lifting and lower device for the loading of the warp beam at ground level with adjustable end positions in line with warp beam dimensions

■ Powered setting of the thrust bearing for the rapid adjustment to differing warp beam widths

■ Pneumatic warp beam ejection

■ Expanding reed with a laying device with 9 segments in a zigzag pattern in the MW700 and 11 in the case of the MW1000

■ Adjustable reed changing device with a stroke of up to 30 mm

■ Leasing device

■ High-definition metre measurement with shift or day counter

■ Programmable warping speed graduation in line with beam start-up

■ Safety devices with safety protection switch

■ Thread tension control device with negatively driven evener rollers for non-elastic yarns

■ Preliminary drafter for elastic yarns

■ Width-adjustable contact device for constant pressure during warping; adjustments can be made during warping

■ Antistatic device with 2 rods

■ Wax or oil device

■ Remote control

■ Warping machine mounted on rollers

■ Load measurement beam for the detection and regulation of thread tension

VIDEO

Catalogs

No catalogs are available for this product.

See all of MÜLLER FRICK‘s catalogsRelated Searches

- Winding machine

- Slitter

- Automatic winder

- Loom

- Automatic winding machine

- Automatic slitter

- Motorized winder

- Fabric slitting machine

- Fabric winder

- High-speed weaving machine

- Creel

- Jacquard weaving machine

- Tape winder

- Textile finisher

- Yarn creel

- Warper

- Winder with meter counter

- Air-jet weaving machine

- Needle weaving machine

- Precision winder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.