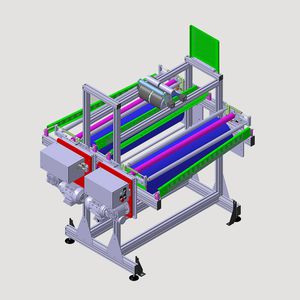

Tape winder SAM-250fabrictrimwith meter counter

Add to favorites

Compare this product

Characteristics

- Product application

- fabric, tape, trim

- Other characteristics

- automatic, with meter counter, precision

Description

Fully automatic, for elastic and non-elastic tapes, braids, cords, trimmings and lace.

■ Important: High productivity

■ Important: Application flexibility

■ Important: Low style change times

■ Important: Convenient operation

■ Important: Microprocessor controlled

■ Important: Winding parameter storage as data record

■ Important: Precise linear measurement

■ Important: Driven tape feeding device

■ Disentangeling device for non-elastic articles

■ Tape inspector “Censor”

■ Over tension shut off

■ Optical length measuring device

■ Mechanical tape brake

■ Tape loop generator

■ Motor driven adjustment tape guide

■ 2 quick change tape guides

■ Tape cutting and end fixing device

■ Traverse drive for bobbins (SAM250 RS)

■ Labeling device

■ Magazine for empty rolls and spools

■ Spool/roll unloading device

■ High winding performance of up to 400 m/min

■ If required, also combinable for bobbin, roll and cartridge bobbin winding

■ Can be used flexibly for a wide range of articles and formats

■ Easy to set and change with programmable and retrievable product parameters

■ Precise measurement of length, also with highly elastic articles

■ Perfect bobbin and roll formation thanks to constant fabric tension and precise guide elements

■ Lateral layering of spool with fixed tape guide for constant tension

■ Micro-processor control for constant, reproducible winding conditions

■ Driven unwinding unit

■ Independent feeder units

■ Integrated feeder device for elastic articles

■ Selectable longitudinal/cross labeling

■ Pinning device

■ Staple device for cords and ribbons

■ Electronically controlled brake for tape tension

■ Cellophaning device for rolls or spools

VIDEO

Catalogs

No catalogs are available for this product.

See all of MÜLLER FRICK‘s catalogsRelated Searches

- Winding machine

- Automatic winder

- Automatic winding machine

- Dyeing machine

- Motorized winder

- Textile dyeing machine

- Yarn winder

- Fabric winder

- Extrusion line winder

- Tape winder

- Continuous dyeing machine

- Adjustable dyeing machine

- Strip fabric dyeing machine

- Winder with meter counter

- Process winder

- Precision winder

- Semi-automatic winder

- Fabric winding machine

- Trim winder

- Weaving machine winder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.