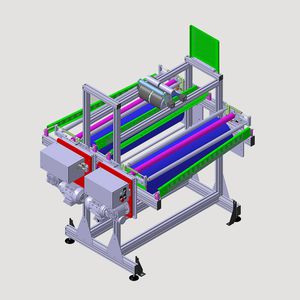

Fabric winder BWWtapemotorizedfor weaving machine

Add to favorites

Compare this product

Characteristics

- Product application

- fabric, tape

- Other characteristics

- motorized, for weaving machine

Description

For the winding of elastic and non-elastic ribbons and lace onto spools and jumbo cores downstream of weaving and crochet machines; all winding positions with same ribbon speed.

This winder has been developed specially for placing after weaving/knitting machines for narrow textiles. It enables narrow fabrics to be wound onto Jumbo centres or flanged bobbins following the weaving/knitting operation.

Winding start and stop as well as adjusting the fabric tension are controlled by a compensator. Laying speed and laying traverse can be matched to the dimensions of the wound package. For a straight build, the reversing point and reversing delay of laying are easily adjusted by the operator.

The result is perfect winding, ideally suited for highly efficient downstream processing on make-up machines or for other processes like dyeing, thermosetting etc.

BWF

As BWW, but located downstream of the dyeing and finishing machines; ribbon speed for each winding head individually selectable.

BWKH

For the winding of hook and loop tapes downstream of the weaving loom.

ZWI

For the winding of light to heavy technical articles on cores in roll form.

This winder is placed immediately after a narrow fabric weaving or knitting machine. It enables up to 6 strips to be wound on large rolls, synchronous to the weaving or knitting operation.

The roll is driven by a shaft in the centre. Side disks may be used with very narrow fabrics or high tensile forces, ensuring a clean roll formation and preventing excessive tensions at the centre.

Catalogs

MÜSONIC3

2 Pages

Related Searches

- Winding machine

- Automatic winder

- Automatic winding machine

- Dyeing machine

- Motorized winder

- Textile dyeing machine

- Yarn winder

- Fabric winder

- Extrusion line winder

- Tape winder

- Continuous dyeing machine

- Adjustable dyeing machine

- Winder with meter counter

- Process winder

- Strip fabric dyeing machine

- Precision winder

- Semi-automatic winder

- Fabric winding machine

- Trim winder

- Weaving machine winder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.