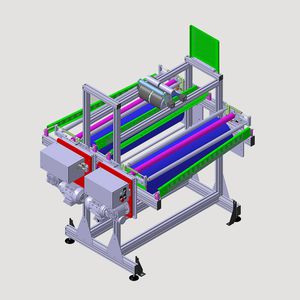

Tape winder RAM-500with meter counterautomaticprecision

Add to favorites

Compare this product

Characteristics

- Product application

- tape

- Other characteristics

- automatic, with meter counter, precision

Description

Fully automatic, for elastic and non-elastic tapes, light to moderately heavy belts and hook and loop tapes on cores.

■ High roll capacity

■ Convenient operation

■ Controlled and reproducible winding tension

■ Microprocessor controlled

■ Winding parameter storage as data record

■ Precise linear measurement

■ Needle and clip mechanism as option

■ Driven tape feeding device

■ Clearly arranged, neat and low-maintenance design

■ High performance through motion sequence with optimized times and motions

■ High operator convenience, easy setting and readjusting when changing tape width, format and winding length thanks to storable production parameters

■ Precision making-up lengths by exactly functioning measuring system

■ Perfect roll formation through repeatable tape tension and precise guidance

■ Constant, repeatable winding speed

■ Pneumatically actuated and interchangeable centre mountings

■ Disentangling and transporting

■ Unwinding drive

■ Measuring for elastic tapes

■ Elastically controlled tape brake for reproducible winding tension

■ Needle device for tape end fixing

■ Clip device for tape end fixing

■ Shaker/conveyor magazine for permanent centre feed, with magazine extension if necessary

■ More powerful gear motor for higher tape tensions

■ Selecting device for rolls not satisfying the programmed quality requirements

Catalogs

RAM-500 /RAM-500KH

4 Pages

Related Searches

- Winding machine

- Automatic winder

- Automatic winding machine

- Dyeing machine

- Motorized winder

- Textile dyeing machine

- Yarn winder

- Fabric winder

- Extrusion line winder

- Tape winder

- Continuous dyeing machine

- Adjustable dyeing machine

- Winder with meter counter

- Process winder

- Strip fabric dyeing machine

- Precision winder

- Semi-automatic winder

- Fabric winding machine

- Trim winder

- Weaving machine winder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.