Grain ventilation system for silos

Add to favorites

Compare this product

Characteristics

- Options

- for grain, for silos

Description

GRAIN VENTILATION SYSTEMS

The main objectives of ventilating a mass of cereal stored in a silo are cooling the cereal and maintaining its temperature in order to keep it in perfect condition and prevent the proliferation of insects and aerobic moulds.

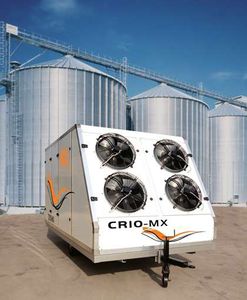

In case of need for greater product cooling, we can supply a CRIO MX trailer-mounted refrigerator that can be connected to the silo ventilation system, by using suitable junctions and suction devices positioned on the roof.

WITH VTP PLATFORM

A galvanised micro-stretched metal sheet is anchored to the silo wall and lays on a structure generally made of concrete blocks. This system guarantees homogeneous air diffusion on the whole surface, however, it can be installed only in small/medium-sized silos.

WITH VTC CHANNEL

Constant-section channels are obtained in the silo base for the passage of air. The channels are covered with pierced hot galvanised metal sheets that can be removed for cleaning but crimped together in order to prevent them from moving. In the upper part they have some oblique slats that permit the passage of air but prevent cereals from infiltrating inside the channel. This ventilation system is used mainly in flat-bottomed silos but can also be reinforced with lorry-resistant elements for use in warehouses.

WITH VTT TUNNEL

Made of modular ducts in galvanised metal micro-perforated sheets, it is mainly used in flat-bottomed warehouses and, by using adequate support beams, in the ventilation of silos with concrete cone bottom. The particular shape and the profile of the duct guarantee extra strength and non-deformability.

Catalogs

No catalogs are available for this product.

See all of MULMIX‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.