- Products

- Catalogs

- News & Trends

- Exhibitions

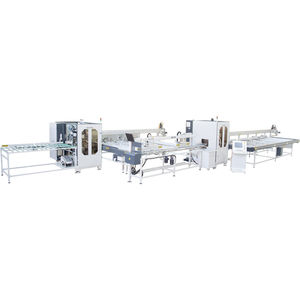

7-axis machining center SC 220 / 40verticalmillingdrilling

Add to favorites

Compare this product

Characteristics

- Number of axes

- 7-axis

- Spindle orientation

- vertical

- Associated functions

- milling, drilling, cutting

- Power

15 kW

(20.39 hp)

Description

All sawing, milling, drilling and marking operations on PVC profiles are gathered in one machine controlled by a computer.

Stacking of 10 profiles (max 6,5 m length)

Automatic cutting in all angles between 30° and 150° with accuracy of 0,1° by means of servo motors

Able to work in high speed and precision thanks to 7 axis controlled by servo motors

Ability to open drain slot routing, drilling and milling at variable angles Automatic conveyor belt system to transport scrap profile to the waste container.

Opens barrel, mirror and handle holes at door profiles simultaneously to increase the production speed by using extra 1 servo motor.

Ability to notify the user against incorrect loaded profile thanks to profile recognition system

Able to perform all operations precisely by the 7 tools on the milling group

Manual barcode labelling system which works integrated with CNC lines

15” touch screen monitor

Industrial PC with Windows XP embedded which works between 0°C - 55°C without fan

Ability to work with the data coming from different window production software by giving minimum wastage

Safe production facility via three dimensional collision and error control system developed by Murat Machine Software Development Department

All errors can be seen on the screen with interface programme developed by Murat Machine Software Development department

Problem identification, solution and servicing by means of remote connections

Data transfer is available via network and connection or USB interface

Ability to back-up daily data on internal storage unit

With shift monitoring system, all operations can be controlled daily, weekly, monthly and yearly

VIDEO

Catalogs

No catalogs are available for this product.

See all of Murat‘s catalogsRelated Searches

- CNC machining center

- Vertical CNC machining center

- 3-axis CNC machining center

- Milling CNC machining center

- Cutting CNC machining center

- Drilling CNC machining center

- Universal CNC machining center

- Steel CNC machining center

- Copy router

- End milling machine

- Profile CNC machining center

- Profile end milling machine

- Copy router

- PVC copy router

- Automatic end milling machine

- PVC profile end milling machine

- Spindle copy router

- Variable-angle end milling machine

- Aluminum copy router

- 7-axis CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.