Design engineers in machine construction still face the challenge of finding innovative lightweight construction solutions for customer-specific problems. One objective is always to increase the efficiency and performance of machines and plants.

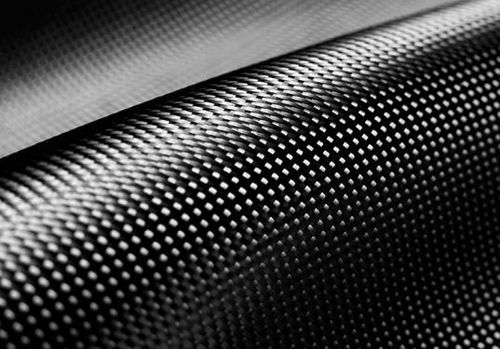

This can be done using fibre-reinforced materials that result in energy conservation, cost reduction, and the improvement of machine properties. Fibre-reinforced materials combine low masses with high rigidity and damping, making them ideal for dynamically stressed machine components.

Murtfeldt offers customers individually manufactured components realized in CFRP or GRP – in the usual Murtfeldt quality: High quality, flexible, fast, for single pieces and/or small series.

Advantages of carbon-reinforced plastic

Carbon-fibre-reinforced plastic has three main advantages: Due to the lower density of the material and its increased strength, the material has an enormous potential for use in lightweight construction, which is advantageous not only for car manufacturing and cycling applications. In addition, CFRP is durable thanks to its inertia and resistance to corrosion and chemicals. And last but not least, the design offers a high level of flexibility.

If design engineers use these specific properties to their advantage, they can tap into huge potentials for machine construction:

By increasing performance and efficiency

For custom solutions by manufacturing individual fibre composite components

By creating unique selling points

With the possibility of integrating a range of functions into a component