- Machine-tools

- Cutting Tool

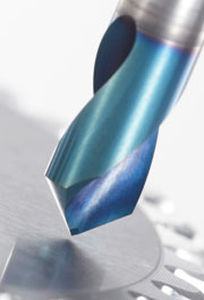

- Solid drill bit

- NACHI America

Solid drill bit AQRVDM5D seriesfor general purposescarbidemicro

Add to favorites

Compare this product

Characteristics

- Type

- solid

- Drilled material

- for general purposes

- Drill bit material

- carbide

- Other characteristics

- micro

- Diameter

Max.: 1.9 mm

(0.07 in)Min.: 0.5 mm

(0.02 in)- Length

38 mm

(1.5 in)

Description

Many problems can arise when drilling with micro diameters;

Low tool life with high risk of sudden breakage

Unstable machining due to variations in hole position

AquaREVO Drills Micro solves those problems with confidence.

An ultra-fine grain cemented carbide was adopted along with original component design to develop a durable substrate for small diameter drills. This provides a material that surpasses the conventional AquaREVO Drills in toughness and hardness.

In order to prevent sudden breakage due to chip jamming, a flute shape that provides optimal web thickness, chip evacuation, and tool rigidity has been adopted.

The coating is a REVO-D coat optimized for micro drills. An ultra-smoothing polishing process reduces resistance during cutting and improves chip evacuation.

Achieves “Long tool life that is hard to break” and “stable cutting with little dispersion” required for small-diameter drills.

Material

Newly developed carbide material for micro drill that is hard to break. Both hardness and toughness are improved by using ultra-fine particles carbide and original component design.

Geometry

Achieves a drill that is hard to break with a flute shape that emphasizes rigidity and chip evacuation. AquaREVO Drills Micro has 1.2 times the breaking torque of competitor’s Drill.

Coating

Stable tool life with accurate film thickness control even with a small diameter drills. Super smooth surface treatment reduces resistance during cutting and improves smooth chip evacuation.

Catalogs

No catalogs are available for this product.

See all of NACHI America‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- General purpose drill bit

- Carbide drilling tool

- Aluminum milling tool

- Twist drilling tool

- High-speed steel drill bit

- Diamond milling tool

- HSS drilling tool

- High-precision milling tool

- Coated drill bit

- Stainless steel drilling tool

- Aluminum drilling tool

- High-performance drilling tool

- Insert drilling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.