- Machine-tools

- Cutting Tool

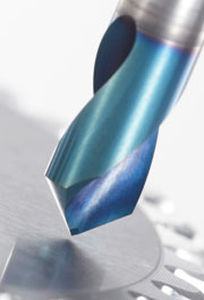

- Solid drill bit

- NACHI America

Solid drill bit AQRVDBL seriesmulti-purposecarbide

Add to favorites

Compare this product

Characteristics

- Type

- solid

- Drilled material

- multi-purpose

- Drill bit material

- carbide

- Diameter

Min.: 2 mm

(0.08 in)Max.: 16 mm

(0.63 in)- Length

Min.: 49 mm

(1.93 in)Max.: 162 mm

(6.38 in)

Description

Suppresing the burrs at the upper side surface of side machining

Overturning the conventional wisdom that “it is natural for burrs to appear during cutting” and “it is natural to remove burrs after machining”, we took on the challenge of minimizing burrs.

It is now possible to eliminate the secondary processing of deburring, which was previously required, resulting in shorter processing times and significant cost reductions.

Suppression of top-side burrs by overwhelmingly using side-surface machining!

R-edge (Radius edge)

Reduced thrust force at exit of hole reducing the structure deformation

Sharp edge cuts without leaving burr

C-point (Center point)

Reducing the hole expansion and uncutten burr from run out of the drills

Burr height (Same diameter cross hole)

Excellent burrless performance on not only for flat surface burr, but also on the cross hole which is difficult to deburring

JINGASA left

No need of next deburring process with no JINGASA left

Almost same tool life as multipurpose Drill

Reducing the burr even near of the end of tool life

Realizes almost same tool life as multipurpose drill even burrless

Catalogs

No catalogs are available for this product.

See all of NACHI America‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- General purpose drill bit

- Carbide drilling tool

- Aluminum milling tool

- Twist drilling tool

- High-speed steel drill bit

- Diamond milling tool

- HSS drilling tool

- High-precision milling tool

- Coated drill bit

- Stainless steel drilling tool

- Aluminum drilling tool

- High-performance drilling tool

- Insert drilling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.