- Machine-tools

- Cutting Tool

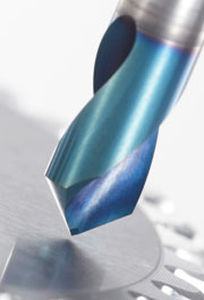

- Solid drill bit

- NACHI America

Solid drill bit SG multi-purpose

Add to favorites

Compare this product

Characteristics

- Type

- solid

- Drilled material

- multi-purpose

- Diameter

Max.: 10.8 mm

(0.43 in)Min.: 2.5 mm

(0.1 in)- Length

Max.: 82 mm

(3.23 in)Min.: 46 mm

(1.81 in)

Description

Zero burrs at the internal diameter of internal thread

Overturning the conventional wisdom that “it is natural for burrs to appear during cutting” and “it is natural to remove burrs after machining”, we took on the challenge of minimizing burrs.

It is now possible to eliminate the secondary processing of deburring, which was previously required, resulting in shorter processing times and significant cost reductions.

Realized Burr zero on internal diameter of internal thread

Long tool life as same as multipurpose Taps

Stable internal diameter accuracy lead Burr zero performance, even near to the end of tool life

Reduces chipping and achieves same tool life equivalent to multipurpose taps

Zero burr with cutting the internal diameter area on internal threadNo gap between thread root area of tap and pre-hole design acheves Zero burr!Chamfered rake face reduce the chipping of cutting edge by chip biting

Catalogs

Related Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- General purpose drill bit

- Carbide drilling tool

- Aluminum milling tool

- Twist drilling tool

- High-speed steel drill bit

- Diamond milling tool

- HSS drilling tool

- High-precision milling tool

- Coated drill bit

- Stainless steel drilling tool

- Aluminum drilling tool

- High-performance drilling tool

- Insert drilling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.