- Machine-tools

- Cutting Tool

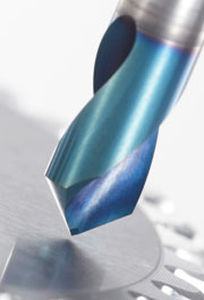

- Solid drill bit

- NACHI America

Solid drill bit AQDEXSN seriesmulti-purposecarbidecoated

Add to favorites

Compare this product

Characteristics

- Type

- solid

- Drilled material

- multi-purpose

- Drill bit material

- carbide

- Other characteristics

- coated

- Diameter

Min.: 3 mm

(0.12 in)Max.: 13 mm

(0.51 in)- Length

Min.: 45 mm

(1.77 in)Max.: 137 mm

(5.39 in)

Description

Coated carbide drill for heat-resistant alloy

Carbide material is optimal for Nickel Alloys, combining excellent wear resistance with chipping resistance.

Flute geometry combines cutting performance with strength to minimize chipping

Highly lubricant AQUA EX coating improves wear resistance, heat resistance, and prolongs tool life.

Material characteristics of heat-resistant alloy and characteristics required for cutting tools

Material characteristics of heat resistant alloy - Cutting conditions - Characteristics required for cutting tools for heat resistant alloy

Highly compatible with tool materials - Poorly finished surface -

Tool materials

Blade break resistance, wear resistance, hardness in hot temperature

Tool shape

Blade shape that optimizes sharpness and strength

Coating properties

Materials with low compatibility with work materials, heat resistance, thermal insulating properties, wear resistance, lubrication properties

Cutting blade chipping

High heat resistance

High cutting temperature

Low thermal conductivity

Subject to tool abrasion

Subject to work hardening

High cutting resistance

Catalogs

No catalogs are available for this product.

See all of NACHI America‘s catalogsRelated Searches

- Milling tool

- Solid milling tool

- Drilling tool

- Clamping milling cutter

- Solid drilling tool

- Metal milling tool

- Milling tool with cylindrical shank

- General purpose drill bit

- Carbide drilling tool

- Aluminum milling tool

- Twist drilling tool

- High-speed steel drill bit

- Diamond milling tool

- HSS drilling tool

- High-precision milling tool

- Coated drill bit

- Stainless steel drilling tool

- Aluminum drilling tool

- High-performance drilling tool

- Insert drilling tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.