- Industrial machines and equipment

- Surface Treatment Equipment

- Dip coating unit

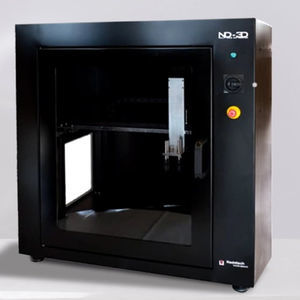

- Nadetech Innovations S.L.

Rotary dip coating unit ND-R

Add to favorites

Compare this product

Characteristics

- Operating mode

- rotary

Description

Rotary Dip Coater is a completely automatized unit for thin films fabrication via dip coating. Up to 8 predetermined positions.

Multilayer thin films by dip coating

LAYER-BY-LAYER

TECHNOLOGY

ELECTROSTATIC SELF-ASSEMBLY

The LbL assembly is a multistep process, in which the different electrostatic attraction forces of the polyelectrolyte solutions keep the coating together.

The almost perfect order at the molecular level of the individual monolayers is the result of many individual molecules reaching their minimum energy configurations locally. They are adsorbed from the aqueous solutions and bind with previously fixed molecules to the substrate. The interpenetration of molecules in adjacent layers can be controlled to improve the macroscopic properties of the material.

LbL technique offers some important advantages in comparison with other coating techniques:

Simplicity: It can be used to coat COMPLEX GEOMETRIES with homogeneous results.

Control: LbL allows to control CONTROL THE THICKNESS of the film.

LbL can be used with nanoparticles, polymers, fluorescent indicators and colorimetric compounds.

VIDEO

Catalogs

ND-R Rotary Dip Coater

4 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.