- Industrial machines and equipment

- Surface Treatment Equipment

- Automatic dip coating unit

- Nadetech Innovations S.L.

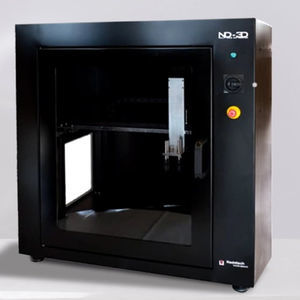

Automatic dip coating unit ND-DC series

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

Description

Dip Coater is a completely automatized unit for thin films fabrication via dip coating like sol-gel, polymeric layers, multilayer structures, biofilms, deposition of antibodies, enzymes and other types of biofilms.

Dip Coating is a widely used deposition technique that can be divided into five steps:

Immersion: The substrate is immersed into a dissolved material

Withdrawal: The substrate which has been dipped for a determinate period of time, starts to withdrawn.

Deposition: The film is deposited on the substrate while it is pulled up. The withdrawal speed determines the thickness of the deposited film.

Drainage: The excess of liquid is drained from the surface.

Evaporation: The solvent is evaporated from the deposited liquid film, resulting in the final coating. Volatile compounds start evaporating.

You can control the coating thickness by managing different parameters. After the deposition, a drying time is necessary. Other post and pre-treatments can be requested.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Nadetech Innovations S.L.‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.