- Packing - Handling - Logistics

- Storage

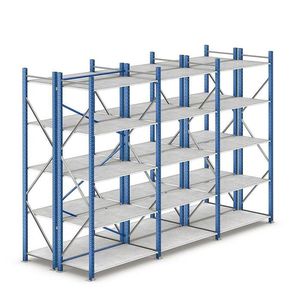

- Storage warehouse shelving

- Nanjing A-Plus Metal Products Co.,Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Storage warehouse racking drive-through pallet3

Add to favorites

Compare this product

Characteristics

- Application domain

- storage warehouse

- Applications

- drive-through pallet

- Number of Shelves

- 3

- Height

10 m

(32'09" )

Description

Drive Through Pallet Racking refers to the storage of pallets one by one from the inside to the outside, the forklift uses the same channel for in and out, the storage density is very good, but the accessibility is poor and it is not easy to achieve first-in-first-out management. As the forklift walks in the entire shelf requires the operator to work carefully, the drive through pallet racking should be 4 layers 3-5 rows.

Drive Through Pallet Racking Features:

1. The storage density is high and the accessibility is poor.

2. Suitable for the storage of little styles and large quantities of items.

4. Stored items are limited by the sequence of skimming positions, and it is not easy to achieve first-in-first-out.

5. Not suitable for items that are too long or too heavy.

Precautions for the purchase of warehouse drive-in racks:

1. Understand the size of the pallet, the direction of the fork, the load capacity of the pallet and the total height of pallet with goods。

2. Warehouse size, height, fire hydrant location, entrance and exit location, etc.

3. Comprehensive data of forklift, max lifting height, max lifting weight, forklift width, turn radius, etc.

The above three points must be considered when designing drive-in racks, and none of them are indispensable.

Other Nanjing A-Plus Metal Products Co.,Ltd products

Heavy Duty Rack

Related Searches

- Storage container

- Rack system

- Stacking container

- Transport container

- Storage crate

- Plastic pallet

- Storage warehouse rack

- Plastic crate

- Stackable crate

- Transport crate

- Metal rack

- Industrial container

- Storage pallet

- Steel rack

- Heavy load rack

- Adjustable rack

- Pallet racking

- Stacking pallet

- Polyethylene pallet

- Industrial crate

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.