- Packing - Handling - Logistics

- Storage

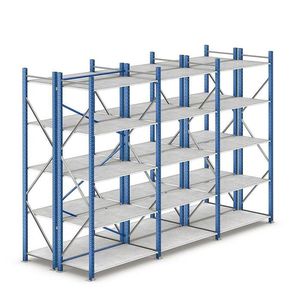

- Picking shelving

- Nanjing A-Plus Metal Products Co.,Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Picking rack for the food industrysingle-sideddrive-in pallet

Add to favorites

Compare this product

Characteristics

- Application domain

- picking, for the food industry

- Configuration

- single-sided, drive-in pallet

- Applications

- pallet

Description

Drive in racks are also called drive through racks, can be used for forklifts (or unmanned trucks with forks) to enter the channel to access the goods, which is suitable for the storage of small types and large batches of goods. Except for the cargo space near the aisle, the forklift needs to enter the rack to access the goods, usually, it is recommended that the single-sided pick-up does not exceed the depth of 7 cargo spaces. In order to increase the operating speed of forklifts, guide rails can be selected according to actual needs. Compared with beam racks, the utilization rate of the storage space of drive-in racks can be increased by more than 30%, widely used in wholesale, cold storage, food and tobacco industries.

Rack Composition

Upright, Horizontal and Diagonal Brace, Vertical Cross Bracing, Plan Cross Bracing, Portal Beam, Spacer, Single and Double Rail Bracket, Floor Guard Rail, Column Guard, etc

Key Features

• Very high utility ratio of the warehouse.

• Can first in - first out or first in - last out.

• Structural steel construction for durability

• Pallet positions configure from 2 to 5 deep and 2 to 5 high deal for roofing.

• Finish: Powder coating and various color be available.

• for storing few type of goods with large quantity.

• Widely used in milk, drink industry, and also be welcomed by cold storage.

Advatanges

1. The cargo storage channel is also a forklift storage and transportation channel, which is a form of rack with higher storage density.

2. Usually used for the storage of goods with fewer varieties but large batches and low requirements for goods picking.

Other Nanjing A-Plus Metal Products Co.,Ltd products

Heavy Duty Rack

Related Searches

- Storage container

- Rack system

- Stacking container

- Transport container

- Storage crate

- Plastic pallet

- Storage warehouse rack

- Plastic crate

- Stackable crate

- Transport crate

- Metal rack

- Industrial container

- Storage pallet

- Steel rack

- Heavy load rack

- Adjustable rack

- Pallet racking

- Stacking pallet

- Polyethylene pallet

- Industrial crate

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.