- Packing - Handling - Logistics

- Storage

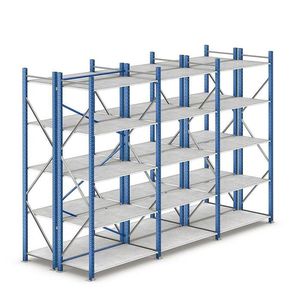

- Box shelving

- Nanjing A-Plus Metal Products Co.,Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

Push-back rack palletfor boxes

Add to favorites

Compare this product

Characteristics

- Inventory management

- push-back

- Applications

- pallet, for boxes

Description

Warehouse storage push back racks:

Push Back” racking works by placing the first pallet on the top cart and pushing it back. This exposes the next cart for loading. When the second pallet is positioned and pushed back, the third cart is ready. This continues until all the pallet positions are filled.

The last pallet sits on the rail itself. When unloading, the front pallet is removed. Gravity moves all the pallets forward to the front for easy access. As each pallet is removed, the remaining pallets move down into position until completely unloaded and all carts are again in position for reloading.

High densities – three and four deep systems are common, which allows blocks of 6 or 8 deep, with back to back rows. Depths of up to 6 deep are also available, at higher costs.

Improved selectivity over Drive-In, which Push-Back often replaces.

Efficiency vs. Drive-In – trucks do not need to drive into rack loads come to them at the pick face.

Less rack. Truck and product damage vs. Drive-In- with no trucks driving inside rack.

Other Nanjing A-Plus Metal Products Co.,Ltd products

Heavy Duty Rack

Related Searches

- Storage container

- Stacking container

- Rack system

- Transport container

- Storage crate

- Plastic pallet

- Storage warehouse rack

- Plastic crate

- Stackable crate

- Transport crate

- Metal rack

- Industrial container

- Storage pallet

- Steel rack

- Heavy load rack

- Adjustable rack

- Pallet racking

- Stacking pallet

- Polyethylene pallet

- Industrial crate

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.