- Production Machines

- Plastics Processing

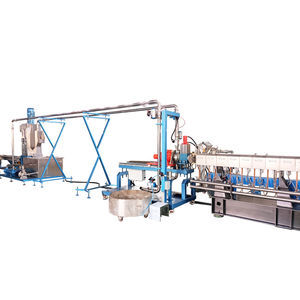

- Pelletizing extruder

- Nanjing Haisi Extrusion Equipment Co., Ltd.

Pelletizing extruder TSE-95B for PVCfor PPfor PE

Add to favorites

Compare this product

Characteristics

- Applications

- pelletizing

- Treated material

- for PVC, for PP, for PE, for ABS, for PET, for PC, for PS, for PMMA, for EVA, for PA

- Number of screws

- single-screw

- Output

Min.: 800 kg/h

(1,763.6981 lb/h)Max.: 1,200 kg/h

(2,645.5471 lb/h)- Screw diameter

93 mm

(3.7 in)- Maximum speed

600 rpm

(3,770 rad.min-1)- Torque

2,506 Nm

(1,848 ft.lb)- Power

315 kW

(428.28 hp)

Description

Long L/D and high torque gearbox for enough reacting time and dispersion.

Special screw elements for premixing the liquid and polymer.

Loss-in-weight feeding system.

The underwater pelletizer is suitable for the production of new materials such as TPU, TPE, hot melt adhesive, PP, PE, PS, ABS, PA, PVC, PC, POM, EVA, LCP, PET, PMMA and Color mixing pelletizing . ideal for processing special material . the underwater pelletizing system can provide the quality granules with excellent performance ,and better smooth appearance.

Advantages of the underwater pelletizing process:

Particle quality advantage:

1. Optimize the shape of the particles, and the surface of the particles is smooth and uniform;

2. High particle density and good fluidity;

3. Eliminate the oxidation of particles;

4. Less bonding;

5. Production and operation advantages:

6.constant pellet quality

about underwater pelletizer

1 Fully automatic continuous production; one-button start-up, convenient and fast.

2.all thermoplastic materials can be processed

3. easy operation,automatic ,safe and fast

4.Shorten the curing time, less floor space and cooling water demand, energy saving and environmental protection.

5.easily accessible pellet dryer, safe cleaning

6.Fully enclosed production, clean working environment, Low noise

7.low labor and maintenance costs

8.optional components for your individual requirements

Catalogs

No catalogs are available for this product.

See all of Nanjing Haisi Extrusion Equipment Co., Ltd.‘s catalogsOther Nanjing Haisi Extrusion Equipment Co., Ltd. products

Thermoplastic Elastomer Extruder

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Panel extrusion line

- Plastic pelletizer

- PVC extrusion line

- Waste granulator

- Single-screw screw extruder

- Polypropylen extrusion line

- Compact pelletizer

- Compounding screw extruder

- PP screw extruder

- PE screw extruder

- ABS screw extruder

- PVC screw extruder

- Compact screw extruder

- Pelletizer for the plastics industry

- Laboratory screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.