- Production Machines

- Plastics Processing

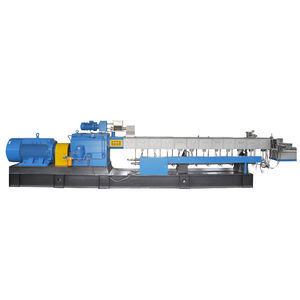

- Pelletizing extruder

- Nanjing Haisi Extrusion Equipment Co., Ltd.

Pelletizing extruder TSE-75Bfor ABStwin-screwcompact

Add to favorites

Compare this product

Characteristics

- Applications

- pelletizing

- Treated material

- for ABS

- Number of screws

- twin-screw

- Other characteristics

- compact

- Output

Max.: 550 kg/h

(1,212.5424 lb/h)Min.: 350 kg/h

(771.6179 lb/h)- Screw diameter

71 mm

(2.8 in)- Maximum speed

600 rpm

(3,770 rad.min-1)- Torque

1,050 Nm

(774 ft.lb)- Power

132 kW

(179.47 hp)

Description

ABS Plastic Granules Making Twin Screw Extruder for Appliance Shell

New-style gear transmission system

1.New-style project of parallel three-axises driving makes the convey axis.convey

2.chain,decelerate and torque get together.which keep it compact.and the key bearings are imported.

3.The compact design to optimize gear parameters and strengthen safe overmeasure.

4.The - seleced material of drive components is dainty. Including super intention alloy

cementiting and grinding.

5.technics,strengthening of tooth face.So they can ensure high torque,high précision and low noise

6.Soakage and spraying lubriation integrate smoothly.

1. - Mixing Nature-Changing

PE/ PP/ PS+SBS; PA+EPDM; PP+NBR; EVA +Silicon rubber, etc.

PE/ PA/ PC/ CPE+ABS(alloy); PBT+PET; PP+ PE, etc.

2. - Filling Nature-Changing

PE/ PP/ EVA, ect. + Calcium carbonate/ talcum powder/ titanic powder;

PP/ PA/ ABS+ ferrous powder/ sulphuric powder/ ceramic powder

3. - Functional Machine Pellets

PE/ PP/ PS, etc+ starch: de-composing machine pellets

PE/ EVA/ ABS, etc.+ carbon black; black machine pellets

4. - Colored Machine Pellets

PE/ PP/ ABS/ AS/ PA/ EVA/ PET +pigment and auxiliary

5.lntensified Glass Fibres And Carbon Fibres

PP/PC/ABS/PET etc. + long fibres/small fibres/carbon fibres and so on.

Catalogs

No catalogs are available for this product.

See all of Nanjing Haisi Extrusion Equipment Co., Ltd.‘s catalogsOther Nanjing Haisi Extrusion Equipment Co., Ltd. products

Engineering Plastic Extruder

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Panel extrusion line

- Plastic pelletizer

- PVC extrusion line

- Waste granulator

- Single-screw screw extruder

- Polypropylen extrusion line

- Compact pelletizer

- Compounding screw extruder

- PP screw extruder

- PE screw extruder

- ABS screw extruder

- PVC screw extruder

- Compact screw extruder

- Pelletizer for the plastics industry

- Laboratory screw extruder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.