In the process of compounding , in order to reduce costs, many film, sheet, profile and pipe manufacturers are adding more and more mineral fillers to their material formulations. For compounding processors, increasing filler content is a new challenge. If the screw and the machine are damaged and corroded by the filling products, it will directly affect the normal operation of the equipment, production efficiency and product quality. For such problems, if you only try to increase the grade of the filler in the single-screw extruder, it is not better to disperse the filler. The twin-screw extruder provided by Nanjing HiSi can make the percentage of calcium carbonate Up to 85%, therefore, a large proportion of fillers are added to the product, which can save a big amount of resin per year and fully recover the cost of the extruder equipment.

twin screw extruder is excellent for master batch production.

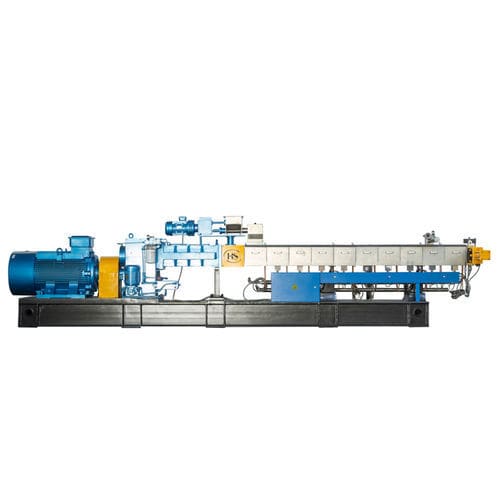

we can also supply two stage extruder for high filler masterbatch manufacturing. it is an ideal solution to provide better performance masterbatch ,