- Production Machines

- Plastics Processing

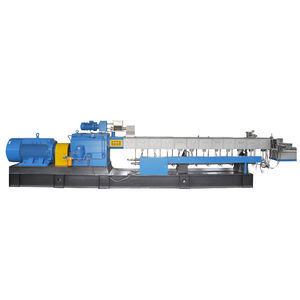

- Pelletizing extruder

- Nanjing Haisi Extrusion Equipment Co., Ltd.

Pelletizing extruder TSE-95for PETfor PSfor ABS

Add to favorites

Compare this product

Characteristics

- Applications

- pelletizing

- Treated material

- for ABS, for PC, for PET, for PS

- Number of screws

- twin-screw

- Output

Max.: 1,200 kg/h

(2,645.5471 lb/h)Min.: 800 kg/h

(1,763.6981 lb/h)- Screw diameter

93 mm

(3.7 in)- Maximum speed

600 rpm

(3,770 rad.min-1)- Torque

2,506 Nm

(1,848 ft.lb)- Power

315 kW

(428.28 hp)

Description

2019 NEW TSE-95 pet recycling plastic pelletizer , suitable for recycled plastic pelletizing . plastic pelletizer machine

this production line suitbale for pc abs ps pelletizing .

This TSE-75B twin screw extruder is Haisi's 2018 lateset design. From the gearbox, screw elements to the assembling of the extruder is all done by ourselves.

Twin screw extruder is widely used for plastic modification, plastic compounding, masterbatch making, as well as hard plastic recycling, such as PET bottles, TPU wastes, ABS shield, etc.

Here is a site photo of machine test running for PET bottle recycling. The pelletizing method is water strand pelletizing.

This four pelletizing methods are the most popular way in plastic granulation.

Also, we supply two stage extruder, single screw extruder, plastic mixer, plastic crusher and other auxiliary machines in plastic extrusion line.

Catalogs

No catalogs are available for this product.

See all of Nanjing Haisi Extrusion Equipment Co., Ltd.‘s catalogsOther Nanjing Haisi Extrusion Equipment Co., Ltd. products

Engineering Plastic Extruder

Related Searches

- Extrusion line

- Thermoplastic extrusion line

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Panel extrusion line

- Plastic pelletizer

- PVC extrusion line

- Waste granulator

- Single-screw screw extruder

- Polypropylen extrusion line

- Compact pelletizer

- Compounding screw extruder

- PP screw extruder

- PE screw extruder

- ABS screw extruder

- PVC screw extruder

- Compact screw extruder

- Laboratory screw extruder

- Pelletizer for the plastics industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.