- Packing - Handling - Logistics

- Conveying

- Belt conveyor

- Nanjing Haisi Extrusion Equipment Co., Ltd.

Belt conveyor horizontalelectric drivefood

Add to favorites

Compare this product

Characteristics

- Technology

- belt

- Form

- horizontal

- Drive mechanism

- electric drive

- Transported product

- food

- Sector

- for the food industry, for the plastics industry, for extrusion lines

- Other characteristics

- cooling

Description

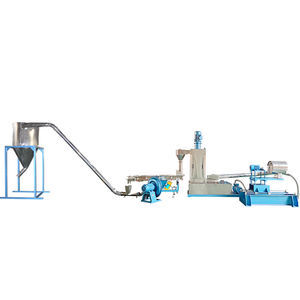

Belt Conveyor with Air-cooling Fan in Plastic Extrusion Line

The belt conveyor with air cooling fan is usually used in dog food making line.

The principle of air cooling strand pelletizing system:

The strips extruded by the twin screw extruder fall on the steel mesh conveyor belt. There are many fans on the conveyor belt. The extruded plastic strips are cooled by fans one by one, and then sent to the pelletizer to complete the granulation of air-cooled strips.

Features of the air cooling strand pelletizing system:

1. Air cooling strand pelletizing system has low cost, simple equipment, and low maintenance costs.

2. The production line of air cooling strand pelletizing system is relatively long, generally 15m~20m.

3. The air cooling strand pelletizing system is suitable for various materials, and the particles made do not contain water. For example,

Elastomers (TPE, TPR, TPU)

Hot melt adhesive (PES, PA, EVA)

High temperature resin (PA6, PA66, PBT, PET)

Degradable plastics (PBS, PLA)

Color masterbatch (PE masterbatch, PP masterbatch, TPU masterbatch)

Catalogs

No catalogs are available for this product.

See all of Nanjing Haisi Extrusion Equipment Co., Ltd.‘s catalogsOther Nanjing Haisi Extrusion Equipment Co., Ltd. products

Cooling and Pelletizing System

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor for the food industry

- Feeder

- Electric drive conveyor

- Stainless steel conveyor

- Food conveyor

- Screw conveyor

- Automatic conveyor

- Powder conveyor

- Spiral conveyor

- Cooling conveyor

- High-precision feeder

- Powder feeder

- Conveying feeder

- High-speed feeder

- Vertical feeder

- Granulate feeder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.