- Detection - Measurement

- Flow, Pressure and Level Measurements

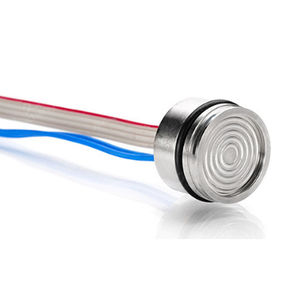

- Absolute pressure sensor

- NANJING JIUCHENG TECHNOLOGY CO., LIMITED

Absolute pressure sensor UC2capacitivecorrosion-resistant

Add to favorites

Compare this product

Characteristics

- Pressure type

- absolute

- Technology

- capacitive

- Protection level

- corrosion-resistant

- Process temperature

Max.: 150 °C

(302 °F)Min.: -65 °C

(-85 °F)

Description

UC2 Capacitive Pressure Sensor Measuring principle

The Ceracore UC2 capacitive pressure sensor is Al2O3 (99.9 %), a highly resistant ceramic material for many aggressive gases and liquids. Cylindrical ceramic components (diaphragm, meter body) are bonded to form a high- strength, hermetically sealed pressure sensor element. With absolute pressure sensors, the vacuum of 3.0 x 10-6 mbar created in the production process between the diaphragm and the meter body remains permanently. This permits pressure measurements related to the vacuum. With gauge pressure sensors, the back of the diaphragm is vented, i.e. this sensor measures the gauge pressure relative to the atmospheric pressure. Electrically, the sensor element represents a plate capacitor whose capacitance change is the dimension for the pressure change. The capacitive measuring process satisfies the highest requirements concerning resolution and reproducibility. Together with the hysteresis-free behavior of the material Al2O3 , it is the basis for the excellent specifications of the sensor. In addition, the Ceracore UC2 capacitive pressure transducer is a dry measuring cell, i.e. there is no separating diaphragm or filling fluid which could influence the measurement. A further advantage of the capacitive ceramic sensor is its high overload resistance. After removal of the overload, it returns to the initial position without any damage or hysteresis.

Dry capacitive ceramic sensor

Basic ceramic material (99.9 % Al2O3)

* Extremely high overload limit

* Absolutely resistant to wear

* High temperature stability

* High long-term stability

* No hysteresis

* Corrosion-resistant

VIDEO

Catalogs

No catalogs are available for this product.

See all of NANJING JIUCHENG TECHNOLOGY CO., LIMITED‘s catalogsOther NANJING JIUCHENG TECHNOLOGY CO., LIMITED products

Ceramic Pressure Sensor

Related Searches

- Pressure transmitter

- Pressure gauge

- Analog pressure transmitter

- Pressure switch

- Pressure probe

- Relative pressure transmitter

- Membrane pressure transmitter

- Waterproof pressure transmitter

- Mechanical pressure switch

- Stainless steel pressure indicator

- Level transmitter

- Digital pressure transmitter

- Liquid level transmitter

- Absolute pressure transmitter

- Gas pressure indicator

- Gas pressure transmitter

- Liquid pressure transmitter

- Waterproof pressure gauge

- Threaded pressure transmitter

- Membrane pressure sensor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.