- Production Machines

- Cutting Machine

- Wood cutting machine

- Nanjing Unitec Technology Co.,LTD

- Products

- Catalogs

- News & Trends

- Exhibitions

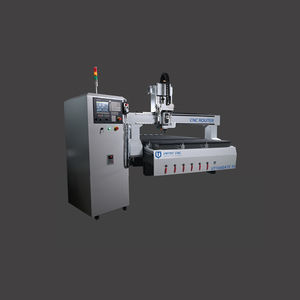

Wood cutting machine UT2050contourCNCmilling

Add to favorites

Compare this product

Characteristics

- Material

- for wood

- Product handled

- contour

- Control type

- CNC

- Associated function

- milling

- Applications

- for industrial applications

- Other characteristics

- high-precision, high-performance, linear

- X travel

2,050 mm

(80.71 in)- Y travel

5,000 mm

(196.85 in)- Z travel

220 mm

(9 in)- Cutting speed

20,000 mm/min

(13.123 in/s)- Weight

3,200 kg

(7,054.79 lb)

Description

1. Air cooling spindle----9 KW Italy HSD atc air cooling spindle.Well-known brands ,long working life,low noise,strong cutting ability to ensure the long time working.

2.Taiwan SYNTEC 4 axis control system----Easy operation. Support offline operation,more table.

3. 850w Japan YASKAWA servo motor----High-performance drive motor to ensure that the machines high speed and accuracy.

4. HIWIN linear rail 25# from Taiwan ----Smooth and precise transmission,low noise,and lifetime is 10 times longer than common rail way.

5. Vacuum & T-slot combined worktable----Can both absorb big materials by vacuum power and fix small materials by clamps. There is MDF boardon it for protection.

Applications and Material

Furniture Industry: wood doorcabinetclassic furniturepanel furnitureetc

Woodworking Industry: Automotive TrimStereo EquipmentInstrumentsOffice FurnitureCloset,etc

ABS Industry Area: Aluminum panel copper soft metal engineering plastic epikote ABS panel

Highlights

1. Integral welded big square steel pipe, mounting surface of guide ail and rack processed by high-precision milling machine, ensure the machine running stability.

2. Big load capacity and long life;Y axis driven by double motors and planetary reducer; High machine rigidity and strong cutting strength ensure non deformation under high speed running.

3. Various of table styles makes convenient clamping materials and improves overall production efficiency.

4. Efficiency; Smooth bottom surface, clear edge contour and fine processing quality.

5. Main configurations adopts imported accessories which will ensure the overall running performance

Other Nanjing Unitec Technology Co.,LTD products

ATC CNC Router Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Fabric cutting system

- Aluminum cutting system

- SS cutting machine

- Sheet cutting system

- CE cutting system

- High-performance cutting system

- Compact cutting system

- Engraving cutting system

- Bridge cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.