- Machine-tools

- Machining Center

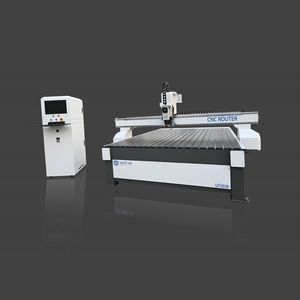

- CNC router

- Nanjing Unitec Technology Co.,LTD

- Products

- Catalogs

- News & Trends

- Exhibitions

CNC router OD-60903-axisdrillingvacuum

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 3-axis

- Applications

- drilling

- Other characteristics

- vacuum, CE

- X travel

600 mm

(23.62 in)- Y travel

900 mm

(35.43 in)- Z travel

150 mm

(5.91 in)

Description

1. Function:A multifunctional model CNC machining center, suitable for routing,relief, drilling, cutting, edge chamfering, etc.

2. Construction:Whole machine table adopts high strength thick steel pipe welded. Whole working table cast by resin sand. The annealing and other heat treatment methods ensure that the whole structure is tested to the limit for sturdiness and reliability.

3. Spare parts: Features world top class mechanical and electronic components, e.g. German rack and pinion, Taiwan rail and ball screw, German reducer, French Shneider electrical components, which guarantee stable performance and high quality.

4. Precision: Excellent spare parts, accurate precision detection instrument, which make sure the machine with perfect location and working precision.

5. High-speed: Adopt reducer direct design, high torque, high-energy, two Y axis motors, runs smoothly with high efficiency.

6. Table: Patented Double Layers of Multi-point Vacuum Absorbable Working Table, Large Suction by Multi-slot. Instant Adsorption, Instant Release

Specification

● Working area: 600X900X150mm

● CE standard

● HQD 9.0KW spindle (ISO30)

● Taiwan Syntec 60W-E

● Active protection safety system

● Helical rack and pinion on X and Y axis, Z axis Taiwan TBI ball screw transmission

● 25mm Hiwin HG Series linear bearing

● Vacuum table+T-solt table

● Japan Yaskawa servo motor and drivers

● Delta brand VFD-B inverter

● Air-tech pro Dust-free extraction hood

● 3 Years Warranty

Other Nanjing Unitec Technology Co.,LTD products

Sign Making CNC Router

Related Searches

- CNC milling machine

- Vertical CNC milling machine

- CNC router

- 3-axis CNC milling machine

- 3-axis router

- Wood router

- Milling machine

- Spindle router

- Precision CNC milling machine

- 3-axis milling machine

- Vertical milling machine

- Swiveling-spindle CNC milling machine

- Plastic router

- High-precision CNC milling machine

- CE router

- Metal router

- Acrylic router

- Furniture router

- Aluminum router

- PVC router

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.