- Industrial machines and equipment

- Furnace and Heat Treatments

- Vacuum dryer

- Nantongtongji Co.,LTD.

- Products

- Catalogs

- News & Trends

- Exhibitions

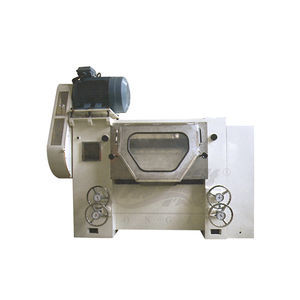

Vacuum drying system continuous

Add to favorites

Compare this product

Characteristics

- Technology

- vacuum

- Batch/continuous

- continuous

Description

Soap Saponification and Vacuum Drying System is making soap noodles through saponification of animal and plant oil and alkali. Saponification gets high temperature liquid soap base, meanwhile adding glycyrin and additives into soap base.After drying, water is evaporated and liquid soap base turnes to solid soap base and extruded as pelletized soap noodles from pelletizer. Soap noodles are of good quality.

Spécifications

Soap Saponification and Drying System Capacity can be 1000kgh to 7000kgh.

Working Principle

Fatty acid is hydrolyzed from raw animal fat or plant oil under high température.

Fatty acid mixes with liquid alkali for neutralization reaction, and soap base is made.

After drying through vacuum drying system, soap base is squeezed to soap noodles through soap refiner.

Features

soap noodles from saponification is of good quality and transparency.

It can be continuous saponification and semi continuous saponification as

customer requests.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.