- Production Machines

- Forming Machine

- Stamping unit

- Nantongtongji Co.,LTD.

- Products

- Catalogs

- News & Trends

- Exhibitions

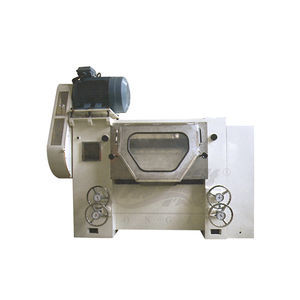

Stamping unit XLD series

Add to favorites

Compare this product

Description

Vertical stamper is equipped with servo control and cam system, reliable and accurate. Control system adopts world famous brand PLC and servo, touch screen and electrical hand wheel, which makes it for operation and adjustment. This machine uses Germany FESTO and Japanese SMC pneumatic elements. It has complete covers with safety door switches to ensure operators’ safety.

Working Principle

Soap billet is eut to specified length and conveyed to stamper. Suction cup sucks soap billet onto mould, stamps, sucks the stamped soaps from mould and place onto the conveyor.

Features

Vertical stamper adopts the best design and technology, driven by servo control and cam system, reliable and high mechanical repeating accu-

racy. According to soap line capacitye and soap size, vertical soap size can

have two moulds installed.

Stamping mould is made of alloy copper. It can be 3 cavities, 4 cavi-

ties, 6 cavities, 8 cavities and 10 cavities, depending on soap weight

and soap size. Suction cup is made of silica gel, with strong suction force and free from scratch on soap.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.