- Power Transmission - Mechanical components

- Actuator and Positioning System

- Z-axis positioning stage

- NATSU PRECISION TRADE LIMITED

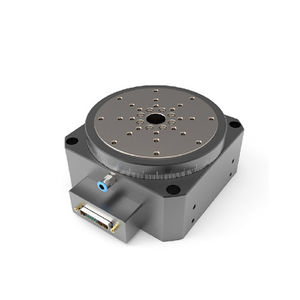

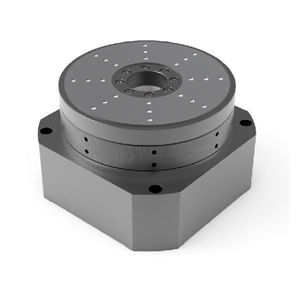

Vertical positioning stage EAB-B250 rotarymotorizedprecision

Add to favorites

Compare this product

Characteristics

- Orientation

- vertical, rotary

- Type

- motorized

- Other characteristics

- precision, compact, measurement, air bearing

Description

•Cleanroom compatible

•Can be mounted vertically or horizontally

•direct-drive, rotary air-bearing stages

•Analog and digital position feedback

Product overview

Delivers best-in-class rotational motion, helping you to optimize your high-precision process

Minimizes axial-, radial-, and tilt-error motions, reducing the need for extensive post-processing of parts and

measurement data

Offers excellent positioning performance and velocity stability with high-resolution feedback

Features a novel, non-influencing motor design that contributes to ultra-precise motion performance

Provides generous load-carrying capacity without compromising on motion quality

Integrates easily into precision systems and machines due to compact, lightweight form factor, as well as horizontal and

vertical mounting and load-carrying capabilities

The motorized rotation stages are designed for accuracy, precision, high stiffness, and ease of use, and can

be mounted in any orientation.

Various options can be combined to create a solution ideal for point-to-point indexing or constant velocity scanning.

The E-ART160 stages offer superior travel accuracy, flatness, and wobble performance. Because they are friction free

and require no maintenance or lubrication, they are ideal for use in cleanrooms.

•torque motor

•Brushless

•Slotless

•Low cogging torque

•Analog and digital position feedback Absolute encoder (optional)

Absolute encoders supply explicit position information that enables immediate determination of the position.

Therefore, no referencing is necessary when switching on and this increases efficiency and safety during operation.

Catalogs

No catalogs are available for this product.

See all of NATSU PRECISION TRADE LIMITED‘s catalogsOther NATSU PRECISION TRADE LIMITED products

Air bearing stages

Related Searches

- Precision STAGE positioning stage

- Precision STAGE linear positioning stage

- Precision STAGE motorized positioning stage

- Precision STAGE precision positioning stage

- 1-axis stage

- Manual stage

- Precision STAGE compact positioning stage

- 2-axis stage

- Precision STAGE XY positioning stage

- Precision STAGE rotary positioning stage

- Precision STAGE multi-axis positioning stage

- Precision STAGE high-accuracy positioning stage

- Piezo stage

- Precision STAGE industrial positioning stage

- Ball screw stage

- 3-axis stage

- Precision STAGE Z-axis positioning stage

- XYZ stage

- Vacuum-compatible stage

- Miniature stage

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.