- Power Transmission - Mechanical components

- Motor and Motor Control

- AC torque motor

- NATSU PRECISION TRADE LIMITED

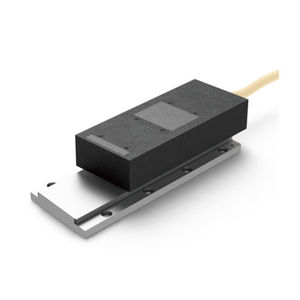

Direct-drive torque motor E-SDM264 SeriesACsynchronouscompact

Add to favorites

Compare this product

Characteristics

- AC/DC

- AC

- Type

- synchronous

- Configuration

- compact, frameless

- Number of poles

- multipole

- Other characteristics

- direct-drive, high-torque, high-precision

- Intensity

4.5 A, 6 A

- Torque

60 Nm, 90 Nm

(44.2537 ft.lb, 66.3806 ft.lb)- Rotational speed

Min.: 0 rpm

(0 rad.min-1)150 rpm

(942.48 rad.min-1)Max.: 200 rpm

(1,256.64 rad.min-1)- Diameter

264 mm

(10.39 in)- Operating temperature

155 °C

(311 °F)

Description

No drive belt adjustment /

replacement

Fewer parts

Better servo performance

Silent operation

●Meaning Of Torque Motor (DD motor)

1. Direct Driver - direct drive。

2. Due to the large torque, it is also called torque servo。

3. High performance embodied in technical indicators - high-quality products in servo product series。

●Product Principle

1. DD motor is literally understood as a direct drive motor, but in fact it is not an ordinary servo, but a

special AC motor with very complex structure, high precision and high performance. It is called direct

drive because it adopts the way of direct connection between the rotor and the moving carrier, and

other transition connections (reducer, coupling, etc.) are no longer used in the middle.

2. The structure of DD motor is divided into inner rotor and outer rotor. The centripetal bearing used

inside can bear a certain axial force. The angular resolution of the encoder is high, generally more

than 500000 PPR (PPR is the number of pulses per revolution). Due to the high-level manufacturing

process and high-precision measurement feedback, the positioning accuracy of this encoder can

reach the angle second level (1 degree = 3600 arcsec).

●Why Choose DD motor

1. High rigidity, compact structure and high efficiency。

2. DD motor has strong rigidity and hard characteristics compared with the load structure, so it has high

requirements for its driver。

3. The unique design of the hollow motor not only reduces its own inertia, but also provides customers with many

installation forms. The combined mechanical structure is more compact and the use efficiency is higher than

other methods.

Catalogs

No catalogs are available for this product.

See all of NATSU PRECISION TRADE LIMITED‘s catalogsRelated Searches

- Electromotor

- AC motor

- Induction motor

- Compact electromotor

- Precision STAGE linear motor

- High-precision motor

- Torque motor

- Precision STAGE high-speed linear motor

- EtherCAT motion control card

- Synchronous torque motor

- Precision STAGE DC linear motor

- Precision STAGE synchronous linear motor

- Direct-drive motor

- Performance torque motor

- AC torque motor

- Multipole torque motor

- Iron-core linear servomotor

- High-torque torque motor

- Direct-drive torque motor

- DC torque motor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.