Foundry vibrating table VTR seriesfresh concrete

Add to favorites

Compare this product

Characteristics

- Applications

- fresh concrete, foundry

Description

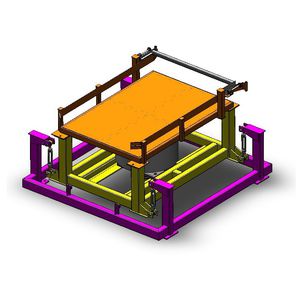

At NetterVibration, we provide a line of vibrating tables designed to vibrate products while they are moving along roller conveyors. This compacts the product in the container, allowing you to transport more bulk material without increasing your load volume. And by integrating vibration into your packaging line, you can compact products while they are in transit, speeding up the process.

Its operation is simple. When the load is on the vibration station, our system raises the container off the rollers and vibrates the load for a few seconds, causing the compaction of the product. Plus, NetterVibration offers the option of installing new rollers or using the rollers already in your roller track.

For more information, please fill out our application questionnaire. We will gladly review your specifications and together we will find the solution that best meets your needs!

• Available with new roller track or can be installed on existing rollers

• Powered by pneumatic or electric vibrator

• Customized design

• Easy to operate

• Variable frequencies

• Variable vibration amplitudes

• Compacting bulk materials

• Testing products for vibration tolerance, including electronics, packaging, automotive components and more

• Smoothing lumps in bulk material

• Flattening bags

Catalogs

No catalogs are available for this product.

See all of Netter Vibration‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.