- Production Machines

- Other Manufacturing Equipment

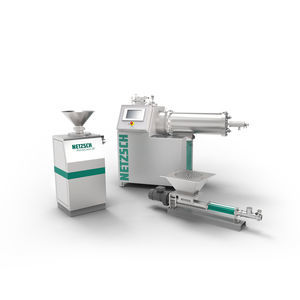

- Knife mill

- NETZSCH Grinding & Dispersing

Knife mill Tango® seriesverticalfor cocoa nibsfor chocolate

Add to favorites

Compare this product

Characteristics

- Technology

- knife

- Orientation

- vertical

- Product applications

- for chocolate, for cocoa nibs, cocoa

- Other characteristics

- fine cutting, powerful

- Sector

- for the food industry

- Output

Max.: 4,000 kg/h

(8,818 lb/h)Min.: 750 kg/h

(1,653 lb/h)

Description

The compact Tango® process plant, designed as a skid, provides an optimum precutting of cocoa nibs to cocoa liquor. Thanks to the efficient precutting process finest cocoa mass will be achieved after one passage on an agitator bead mill type MasterRefiner.

Both mills, supply pump and control unit are mounted on a skid forming a space-saving compact unit easy to handle and easy to assemble.

An intermediate tank is not necessary for this process. The cocoa mass pre-cut on the beater blade mill type MasterNibs is supplied by a pump to the agitator bead mill type MasterRefiner for fine grinding in one passage.

The on-top-drive oft the MasterNibs allows additional cooling in the lower part of the beater blade mill tank. This does not only bring about flavor-preserving temperatures during the pre-crushing of cocoa nibs but also simplifies and essentially shortens the time required for maintenance and cleaning of the MasterNibs.

The drive from upper part allows better access to tools and chamber

Bearing in the upper part, bottom can be used for cooling, lower temperatures

Exchange of beaters done outside the chamber in very short time

Easy and fast cleaning of chamber, tools and screen

Efficient single pass operation

High throughput

Foot print saving

Allows smaller beads and finer product

Reducing of lifecycle costs (TCO)

Catalogs

No catalogs are available for this product.

See all of NETZSCH Grinding & Dispersing‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other NETZSCH Grinding & Dispersing products

Confectionery Systems

Related Searches

- NETZSCH mill

- NETZSCH horizontal mill

- NETZSCH vertical mill

- NETZSCH food mill

- NETZSCH rotor mill

- NETZSCH impact mill

- Knife chopper

- Plastic pulverizer

- Mill for the pharmaceutical industry

- Grinding mill for the food industry

- Stainless steel grinding mill

- NETZSCH laboratory mill

- NETZSCH compact mill

- Mineral mill

- NETZSCH powder mill

- NETZSCH dry milling mill

- Rotary drum grinding mill

- Ball grinding mill

- Metal mill

- High-speed grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.