- Industrial machines and equipment

- Mixing and Dosing

- Rotor-stator homogenizer

- NETZSCH Grinding & Dispersing

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

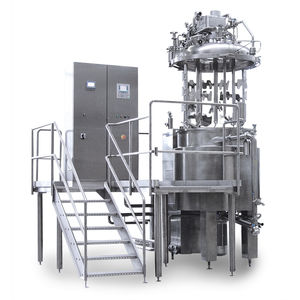

Rotor-stator homogenizer LambdaVita CONTIin-linefor liquidsvertical

Add to favorites

Compare this product

Characteristics

- Technology

- rotor-stator

- Batch/continuous

- in-line

- Product type

- for liquids

- Configuration

- vertical

- Other characteristics

- disperser

- Applications

- for the pharmaceutical industry, for the cosmetics industry

Description

The design of the homogenizer determines the quality of your dispersions.

Only with optimum utilization of the shear energy can the required particle/droplet sizes and size distributions be achieved. In addition to economy, efficiency is paramount when selecting a homogenizer. And of course, a universal application for your various products must be possible.

Our particular focus is on the development of an optimal tooth geometry, on the dispersion toothing, as well as on the design of the entire homogenizing system, in order to produce both the highest shear rates / shear energies and thus to ensure the finest droplets / particles. In addition, all homogenizers of the LambdaVita® series are CIP-capable.

The homogenizers ensure high flow rates, especially in the upper vacuum range. With the NETZSCH Vakumix homogenizer we meet all the demands of the market.

A variety of options and versions makes the following possible for you:

• Homogenization

• Dispersing

• Suction of different phases directly into the area of the homogenizer (e.g. hot-cold)

• Dilution of ether sulfate in a continuous process

• Induction of powders

• Dosed feeding of liquid phases at the same time

• and much more

Configurable production plant for continuous manufacturing

Catalogs

No catalogs are available for this product.

See all of NETZSCH Grinding & Dispersing‘s catalogsOther NETZSCH Grinding & Dispersing products

Dispersing & Homogenizing

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- NETZSCH mill

- Liquid agitator

- Agitator for the chemical industry

- NETZSCH horizontal mill

- NETZSCH vertical mill

- NETZSCH food mill

- Agitator for the pharmaceutical industry

- NETZSCH rotor mill

- Paddle blender

- Construction agitator

- Turbine agitator

- Homogenizer

- NETZSCH impact mill

- Homogenizer for the cosmetics industry

- Compact agitator

- Dynamic homogenizer

- Vacuum homogenizer

- High-speed homogenizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.