- Production Machines

- Other Manufacturing Equipment

- Wet mill

- NETZSCH Grinding & Dispersing

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

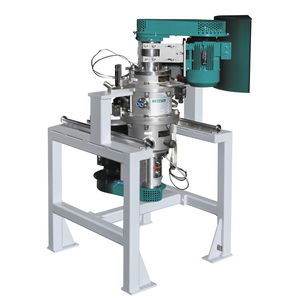

Wet grinding mill DeltaVita® 600horizontalfor powderslaboratory

Add to favorites

Compare this product

Characteristics

- Technology

- wet

- Orientation

- horizontal

- Product applications

- for powders

- Other characteristics

- laboratory, micronization, stainless steel

- Sector

- for the pharmaceutical industry

Description

The comminution or desagglomeration of active pharmaceutical ingredients (API) is called micronization and brings about several advantages. The increase of the particle surface caused by the comminution results in a considerably better dissolution rate and bioavailability of the agents and therefore the APIs act faster. Due to the increased bioavailability a lower amount of APIs is required which in turn leads to a more cost-efficient product with less risks and side effects for the patient.

• All product wetted parts are designed and manufactured according to the latest GMP standards

• Material, production and calibration certificates are supplied together with the machine

• Optional cleaning in place (CIP) and sterilization in place (SIP)

• All indirectly product-wetted surfaces are made of stainless steel

• Optional data recording and formulation management

• Operator management with password protection for different levels of security

• Laboratory mills can be used with variable grinding chamber sizes

• Various materials like NETZSCH-Ceram Z, stainless steel 316 or nylon grinding chamber designs are available

• Splash-proof machine stand

• Comprehensive testing and qualification documentation, FAT, IQ, OQ, process validation

• Trainings and seminars

• Interchangeable agitating systems

• Optional explosion-proof design for installation in hazardous areas

• PLC control with optional interface for data acquisition

• Optional CIP and SIP ready

VIDEO

Catalogs

No catalogs are available for this product.

See all of NETZSCH Grinding & Dispersing‘s catalogsOther NETZSCH Grinding & Dispersing products

Laboratory Machines

Related Searches

- NETZSCH mill

- NETZSCH horizontal mill

- NETZSCH vertical mill

- NETZSCH food mill

- NETZSCH rotor mill

- NETZSCH impact mill

- Knife chopper

- Plastic pulverizer

- Mill for the pharmaceutical industry

- Grinding mill for the food industry

- NETZSCH laboratory mill

- Stainless steel grinding mill

- NETZSCH compact mill

- NETZSCH dry milling mill

- NETZSCH powder mill

- Rotary drum grinding mill

- Ball grinding mill

- Metal mill

- High-speed grinding mill

- Disc pulverizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.