- Production Machines

- Other Manufacturing Equipment

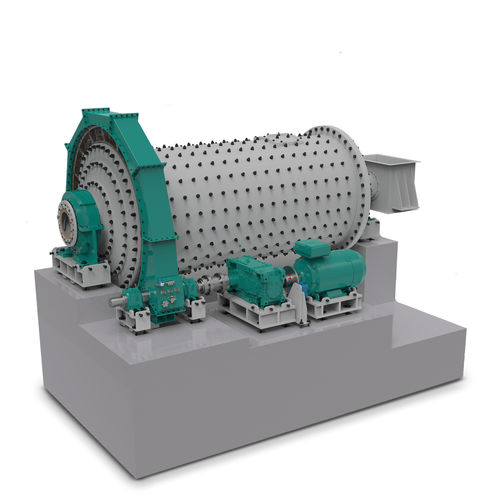

- Ball mill

- NETZSCH Grinding & Dispersing

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Ball grinding mill Taurusimpactverticalfor powders

Add to favorites

Compare this product

Characteristics

- Technology

- ball, impact

- Orientation

- vertical

- Product applications

- for powders, for coal grinding

- Other characteristics

- micronizing, robust

Description

NETZSCH Ecutec's Taurus has the most advanced technology in Mills using Grinding Media for micronizing.

A rotating robust steel drum with liners is supplying kinetic energy to grinding media inside the mill. These grinding media are crushing and grinding fresh product due to impact and friction. The lining as well as the grinding media can be made out of hard wear resistant high manganese/chromium steel, ceramic or silex.

The Taurus has several available configurations depending on the application and mill size. NETZSCH Ecutec also carries an extensive selection of special grinding media to optimize the performance of the ball mill specific to the customer's requirements. Together with NETZSCH Ecutec classifiers, the Taurus provides a wide range of fineness with top cuts down to d98 < 2 μm and up to d98 300 μm. The Taurus guarantees the best performance due to its high manufacturing quality, endurance, an low maintenance needs. This machine is the best solution for fine to ultra-fine processing of a wide variety of materials.

• Wide fineness ranges between

• d98 < 2 μm - 300 μm

• High volume capacities due to its advanced design

• Lenghthy durability, therefore low maintenance costs

• Trouble-free, reliable operation

• Tailor-made solutions available

• Lab Sizes available

Catalogs

Other NETZSCH Grinding & Dispersing products

Dry Grinding

Related Searches

- NETZSCH mill

- NETZSCH horizontal mill

- NETZSCH vertical mill

- NETZSCH food mill

- NETZSCH rotor mill

- NETZSCH impact mill

- Knife chopper

- Plastic pulverizer

- Mill for the pharmaceutical industry

- Grinding mill for the food industry

- NETZSCH laboratory mill

- Stainless steel grinding mill

- NETZSCH compact mill

- NETZSCH dry milling mill

- NETZSCH powder mill

- Rotary drum grinding mill

- Ball grinding mill

- Metal mill

- High-speed grinding mill

- Disc pulverizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.