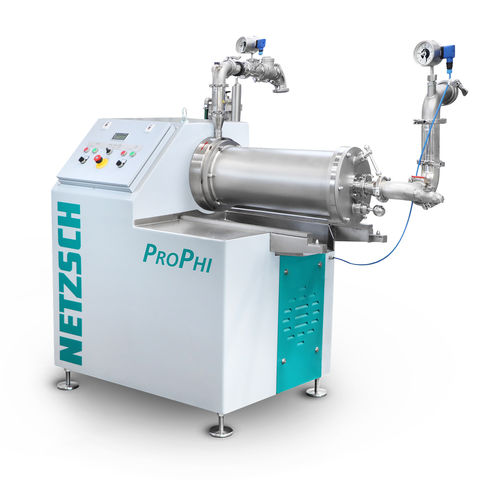

Increase product capacity, save energy, shorten production time and ensure reproducibility - all this is possible with the new ProPhi pre-grinding unit from NETZSCH.

This new technology improves your dispersion process so that all subsequent production steps benefit. With the ProPhi you will reduce your premixing process time by up to 50% and your cleaning effort for large batches. In addition, you can process sedimentation-prone materials and fluctuating raw material qualities without jeopardizing your process reliability.

• High product quality: for stable rheological product properties (no sedimentation after pre-dispersion)

• High process reliability, even with fluctuating raw material qualities

• Sustainable production

• Reduction in energy consumption by up to 30%

• Mminimal cleaning effort for large batches

• Reduction in investment costs and spare parts through the use of highly resistant materials

• Smaller grinding beads can be used for fine grinding - conditional energy savings

• High productivity: reduction of the premixing process time by up to 50%

The NETZSCH ProPhi crushes difficult-to-handle coarse material with the most effective physical operating principles. Pre-dispersion of agglomer-ates, which is usually carried out discontinuously or continuously in intensive mixing units, can also be carried out without any problems. This re-quires prior introduction of the solids into the liquid phase. A major challenge in the continuous preparation of coarse suspensions is their ten-dency to sedimentation, which can be solved by a correspondingly high flow rate and a high product throughput.