- Production Machines

- Other Manufacturing Equipment

- Impact mill

- NETZSCH Grinding & Dispersing

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

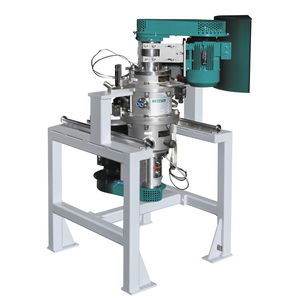

Impact mill Uralfor powdersultrafinecompact

Add to favorites

Compare this product

Characteristics

- Technology

- impact

- Product applications

- for powders

- Other characteristics

- ultrafine, compact, classifier

Description

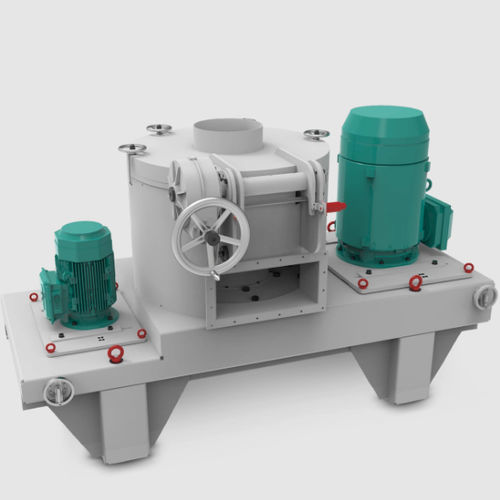

NETZSCH ECUTEC's Ural - Air Classifier Mills combine high classifying efficiency with the advantages of a multi-purpose mill.

NETZSCH Ecutec Ural Air Classifier Mill is an impact grinding system with an integrated classifier and therefore ideal for products with steep particle size distributions. The multipurpose mill can be used for soft and medium hard minerals where wear resistant materials can be chosen. The mill can be equipped with different grinding housing as well as different impact elements, depending on the product and final product specs.

There are also several designs and materials available for the classifier, depending on the product and final particle size:

• Mild Steel

• Hardened Steel

• Ceramics

NETZSCH Ecutec`s Ural can be operated with ambient air, hot air as well as dried and cooled air which covers a wide range of mineral applications. The mill combines drying, grinding and classifying processes in one compact unit.

Ural has been designed with a grinding disc and classifier rotor, which are attached to a double shaft. This design and the operation with VFD's makes it possible to adjust the rpm's of grinding and classifying independently. Product ground by the high impact forces of the grinding disc is delivered to the classifier where fine product is accepted and coarse is rejected back into the grinding zone.

There are two air inlets: the main air inlet at the bottom of the mill disc and another which is used to feed the fresh product. Product accepted by the classifier will leave the mill on the top section through a center opening, connecting the mill to a final product filter or cyclone.

Catalogs

URAL | Air classifier mill

4 Pages

Other NETZSCH Grinding & Dispersing products

Dry Grinding

Related Searches

- NETZSCH mill

- NETZSCH horizontal mill

- NETZSCH vertical mill

- NETZSCH food mill

- NETZSCH rotor mill

- NETZSCH impact mill

- Knife chopper

- Plastic pulverizer

- Mill for the pharmaceutical industry

- Grinding mill for the food industry

- NETZSCH laboratory mill

- Stainless steel grinding mill

- NETZSCH compact mill

- NETZSCH powder mill

- NETZSCH dry milling mill

- Rotary drum grinding mill

- Ball grinding mill

- Metal mill

- High-speed grinding mill

- Disc pulverizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.