- Production Machines

- Other Manufacturing Equipment

- Jet mill

- NETZSCH Grinding & Dispersing

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

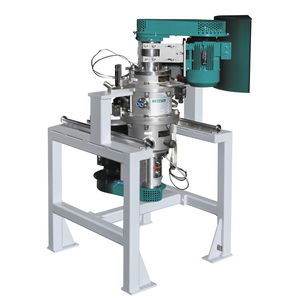

Fluidized bed jet mill CGShorizontaldry millingvariable speed

Add to favorites

Compare this product

Characteristics

- Technology

- fluidized bed jet

- Orientation

- horizontal

- Other characteristics

- dry milling, variable speed, ultrafine, air classifier

Description

This innovative air jet mill is capable of fine grinding all kinds of dry products with virtually no contamination.

Through this specialized milling concept, product grinding is entirely autogenous. Gas jets alone create the grinding energy. No tool wear occurs!

An integrated dynamic air classifier in the housing can be infinitely adjusted to the desired fineness. This guarantees exact adjustment of the grinding parameters and reproducible product quality.

Even the hardest of products poses no problem for this machine. In addition, extremely temperature sensitive products such as wax can be processed under continuous operation.

Where air jet mills not economical for your product and application in the past? Not anymore! We have closely examined the energy efficiency of this technology. The result is a completely new grinding method.

Until now air jet milling, due to its energy consumption, was only cost efficient when applied to high value products. Now many other materials can be economically processed in our fluidized bed jet mills.

Economy is only one of the distinguishing features of our new e-Jet® System (patent pending). Process optimization through the adaptation of grinding conditions provides energy savings of up to 30 % compared to the conventional operation of air jet mills. Products that in the past could only be economically processed in mechanical mills, can now be micronized even more economically in our CGS Fluidized Bed Jet Mill using the e-Jet® System.

VIDEO

Catalogs

Other NETZSCH Grinding & Dispersing products

Dry Grinding

Related Searches

- NETZSCH mill

- NETZSCH horizontal mill

- NETZSCH vertical mill

- NETZSCH food mill

- NETZSCH rotor mill

- NETZSCH impact mill

- Knife chopper

- Plastic pulverizer

- Mill for the pharmaceutical industry

- Grinding mill for the food industry

- NETZSCH laboratory mill

- Stainless steel grinding mill

- NETZSCH compact mill

- NETZSCH powder mill

- NETZSCH dry milling mill

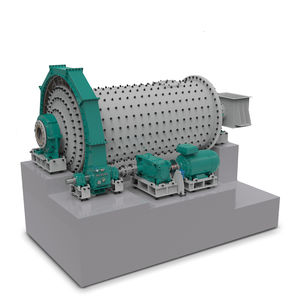

- Rotary drum grinding mill

- Ball grinding mill

- Metal mill

- High-speed grinding mill

- Disc pulverizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.