- Production Machines

- Other Manufacturing Equipment

- Rotor mill

- NETZSCH Grinding & Dispersing

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

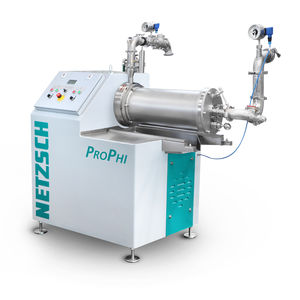

Rotor mill Zeta®horizontalfor metalsfor ceramics

Add to favorites

Compare this product

Characteristics

- Technology

- rotor

- Orientation

- horizontal

- Product applications

- for metals, for ceramics

- Other characteristics

- high-speed, nano

Description

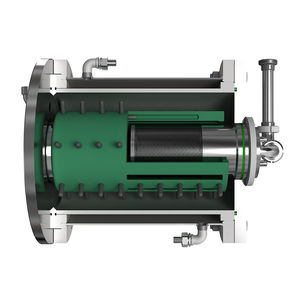

The high-speed mill system Zeta® with improved peg grinding system optimizes your production capacity, energy demand and quality. Designed for circulation operation and multi-pass operation, you achieve high throughput rates and high quality with a narrow particle size distribution for higher viscous products.

A minimal control expenditure is necessary to guarantee highest reproducibility and save additional costs. The large dimensioned rotor with slotted pipe separation enables the use of very small grinding media of different materials. Special grinding chamber designs of ceramic (NETZSCH Ceram C, NETZSCH Ceram N, NETZSCH Ceram Z) and NElast are available for metal-free processing of your products.

• Peg grinding system with high volume specific power density of 2 kW/dm3

• Small length-/diameter proportion

• Designed for highest product throughputs (passage & circulation)

• Narrow residence time spectrum at lowest specific energy input

• Highly efficient centrifugal separation system

• Use of smallest grinding media (down to 90 µm)

• Exchangeable grinding chamber components of wear and corrosion resistant materials, adapted to your application

• Simple integration into production plants

• Applicable in a very wide viscosity range (from 20 mPas - 7000 mPas)

• Low product temperatures due to intensive cooling of the grinding tank and the agitator shaft (Zeta® II design also available with rotor cooling)

• Easy handling and process control

• Easy access to the separation system

• Grinding tank with lifting device

VIDEO

Catalogs

Other NETZSCH Grinding & Dispersing products

Wet Grinding

Related Searches

- NETZSCH mill

- NETZSCH horizontal mill

- NETZSCH vertical mill

- NETZSCH food mill

- NETZSCH rotor mill

- NETZSCH impact mill

- Knife chopper

- Plastic pulverizer

- Mill for the pharmaceutical industry

- Grinding mill for the food industry

- NETZSCH laboratory mill

- Stainless steel grinding mill

- NETZSCH compact mill

- NETZSCH dry milling mill

- NETZSCH powder mill

- Rotary drum grinding mill

- Ball grinding mill

- Metal mill

- High-speed grinding mill

- Disc pulverizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.