- Hydraulics - Pneumatics

- Pump

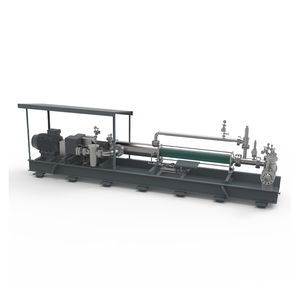

- Progressive cavity pump

- NETZSCH Pumps & Systems

Aseptic pump NEMO® SAprogressive cavityfor chemicalsfor food products

Add to favorites

Compare this product

Characteristics

- Technology

- progressive cavity

- Fluid

- for chemicals, for food products

- Operation

- with electric motor

- Priming

- self-priming

- Mobility

- stationary

- Domain

- for the chemical industry, for the pharmaceutical industry, for the food industry, for the cosmetics industry, for hygienic applications

- Applications

- transfer, metering, conveying

- Protection level

- maintenance-free

- Other characteristics

- constant-pressure, aseptic

- Flow

Min.: 0.7 m³/h

(24.72027 ft³/h)Max.: 120 m³/h

(4,237.76001 ft³/h)- Pressure

12 bar, 24 bar

(174.045 psi, 348.091 psi)

Description

The ideal partner for conveying in hygienic and aseptic environments, the NEMO® SA aseptic pump features a bearing housing with a maintenance-free flexible rod, ensuring a crevice-free design. It is utilized for its cleanability (CIP/SIP process) in aseptic and hygienic applications across the food, pharmaceutical, cosmetic, and chemical/biochemical industries, providing continuous, pressure-stable, gentle, and low-pulsation conveyance, as well as dosing proportional to speed. To prevent contamination from the surrounding environment, all hermetic areas can be sealed with steam or sterile condensate. This progressing cavity pump offers versatility and is particularly effective with bacteriologically sensitive, toxic, contaminated, shear-sensitive, low to highly viscous, lubricating, non-lubricating, solids-containing or solids-free, thixotropic, dilatant, abrasive, and adhesive media. Various regulatory bodies have established specifications for the hygienic configuration of components and machinery, as well as for component cleanability (CIP/SIP process). NEMO® SA aseptic pumps are designed, manufactured, and inspected in accordance with the regulations of the FDA (Food and Drug Administration) and EU-VO 1935/2004. Additionally, they meet the specifications of the United States’ 3-A Sanitary Standards and hold GOST-R certification (a Russian certificate of conformity). The design featuring a bearing housing and free shaft end enables the universal use of all types of drives.

Catalogs

No catalogs are available for this product.

See all of NETZSCH Pumps & Systems‘s catalogsOther NETZSCH Pumps & Systems products

NEMO® Progressing Cavity Pump

Related Searches

- Netzsch pump

- Netzsch industrial pump

- Netzsch electric pump

- Netzsch stationary pump

- Netzsch water pump

- Netzsch self-priming pump

- Netzsch chemical pump

- Stainless steel pump

- Netzsch lubricant pump

- Netzsch transfer pump

- Netzsch pump for the chemical industry

- Netzsch compact pump

- Netzsch oil pump

- Submersible pump

- Flow pump

- Netzsch food product pump

- Netzsch discharge pump

- Netzsch metering pump

- Work pump

- Standard pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.