- Hydraulics - Pneumatics

- Pump

- Progressive cavity pump

- NETZSCH Pumps & Systems

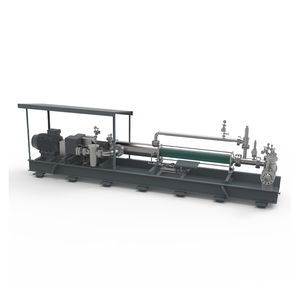

Cutter pump NEMO® BO/SO progressive cavityfor food productswith electric motor

Add to favorites

Compare this product

Characteristics

- Technology

- progressive cavity

- Fluid

- for food products

- Operation

- with electric motor

- Mobility

- stationary, mobile

- Domain

- industrial, for the food industry

- Applications

- metering, conveying, macerator

- Fluid specification

- for solids-laden fluids

- Other characteristics

- cutter

- Flow

Max.: 16 m³/h

(565.03467 ft³/h)Min.: 0.6 m³/h

(21.1888 ft³/h)- Pressure

12 bar

(174.045 psi)

Description

The NEMO® BO/SO hopper pump with integrated cutting device enables conveying and cutting in one process step without the need for expensive additional equipment. This progressing cavity pump allows large solids, such as fruit or vegetable particles, to be easily and quickly chopped and pumped for further processing, particularly in the food industry. The NEMO® BO/SO progressing cavity pump, featuring a hopper and a coupling rod with feeding screw and force-feed chamber, is used across almost all industrial sectors. It ensures continuous, pressure-stable, gentle, and low-pulsation conveyance. The hopper housing with the cutting unit guarantees optimal feeding of chunky medium into the conveying elements. As the medium passes through the force-feed chamber with the cutting unit, larger pieces of fruits and vegetables are immediately cut. This cutting unit consists of a rotating knife with three blades and a variable number of stationary knives, which can be adjusted to the size and consistency of the particles.aintenance costs. However, it is also available in bearing block design with a free shaft end.

Catalogs

No catalogs are available for this product.

See all of NETZSCH Pumps & Systems‘s catalogsOther NETZSCH Pumps & Systems products

NEMO® Progressing Cavity Pump

Related Searches

- Netzsch pump

- Netzsch industrial pump

- Netzsch electric pump

- Netzsch stationary pump

- Netzsch water pump

- Netzsch self-priming pump

- Netzsch chemical pump

- Stainless steel pump

- Netzsch lubricant pump

- Netzsch transfer pump

- Netzsch pump for the chemical industry

- Netzsch compact pump

- Netzsch oil pump

- Submersible pump

- Flow pump

- Netzsch food product pump

- Netzsch discharge pump

- Netzsch metering pump

- Work pump

- Standard pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.