- Hydraulics - Pneumatics

- Pump

- Progressive cavity pump

- NETZSCH Pumps & Systems

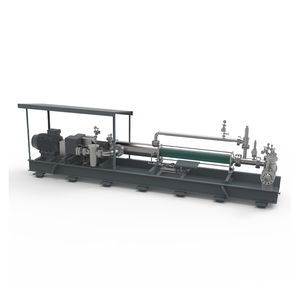

Pump with feed hopper NEMO® BFprogressive cavityfor wastewaterslurry

Add to favorites

Compare this product

Characteristics

- Technology

- progressive cavity

- Fluid

- for wastewater, slurry, for food products

- Operation

- with electric motor

- Mobility

- stationary

- Domain

- industrial, for wastewater treatment, for the food industry, for methanizers

- Applications

- transfer, metering, feed, conveying

- Fluid specification

- for solids-laden fluids, for high-viscosity fluids

- Other characteristics

- compact, with feed hopper

- Flow

Min.: 0 m³/h

(0 ft³/h)Max.: 60 m³/h

(2,118.88 ft³/h)- Pressure

Min.: 0 bar

(0 psi)Max.: 36 bar

(522.136 psi)

Description

The NEMO® BF hopper-shaped progressing cavity pump with aBP-Module® to prevent bridging is utilized across all industries for continuous, pressure-stable, gentle, and low-pulsation conveyance, as well as speed-proportional dosing, particularly for highly viscous, compacted, and crumbly media. To ensure optimal product feed into the conveying elements, the pump housing is designed with an enlarged, rectangular feed hopper and a conical force-feed chamber, along with a special coupling rod featuring a patented, positioned conveying screw. The additional aBP-Module® (asynchronous Bridge Preventing) consists of a top shaft with two internal spoke wheels. These components create "moving shaft walls" that exert a shearing effect on the medium, reliably preventing bridge formation in the pump shaft. This guarantees the smooth conveyance of solid-laden, shear-sensitive, abrasive, adhesive, thixotropic, or dilatant materials, as well as lubricating and non-lubricating substances prone to bridging. The NEMO® is particularly compact and economical in its block construction with a flanged drive.

Catalogs

No catalogs are available for this product.

See all of NETZSCH Pumps & Systems‘s catalogsOther NETZSCH Pumps & Systems products

NEMO® Progressing Cavity Pump

Related Searches

- Netzsch pump

- Netzsch industrial pump

- Netzsch electric pump

- Netzsch stationary pump

- Netzsch water pump

- Netzsch self-priming pump

- Netzsch chemical pump

- Stainless steel pump

- Netzsch lubricant pump

- Netzsch transfer pump

- Netzsch pump for the chemical industry

- Netzsch compact pump

- Netzsch oil pump

- Submersible pump

- Flow pump

- Netzsch food product pump

- Netzsch discharge pump

- Netzsch metering pump

- Work pump

- Standard pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.