- Production Machines

- Other Manufacturing Equipment

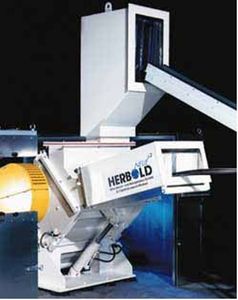

- In-line mill

- NEUE HERBOLD Maschinen-u. Anlagenbau GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

In-line mill SMV Seriesedge trim

Add to favorites

Compare this product

Characteristics

- Other characteristics

- in-line, edge trim

Description

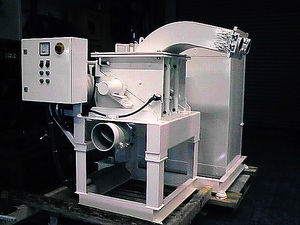

These granulators/cutting mills come with a roller feeder. The granulator features a rear entry roller feed, which allows material to be fed from a bench winder. The edge trim should be discharged continually and then automatically recycled back without line operators being required.

There are many advantages with these cutting mills. There is no mixing and/or contamination risk caused by temporary storage or the transport process. Continual mainstream feeding of virgin and recycled material allows for materials and money to be saved. There is also no need for personnel and extra space for separate material processing.

Specific application solutions are developed and provided for extrusion needs. Consumers can receive a fine tuned system for their applications.

Catalogs

No catalogs are available for this product.

See all of NEUE HERBOLD Maschinen-u. Anlagenbau GmbH‘s catalogsOther NEUE HERBOLD Maschinen-u. Anlagenbau GmbH products

Granulators

Related Searches

- NEUE HERBOLD mill

- Screening unit

- Bulk material screening unit

- Horizontal grinding mill

- Vertical grinding mill

- Food lump breaker

- NEUE HERBOLD rotor mill

- Vibrating sieving machine

- Impact grinding mill

- Waste lump breaker

- Recycling screening unit

- NEUE HERBOLD knife mill

- NEUE HERBOLD plastic mill

- Hammer grinding mill

- Mill for the pharmaceutical industry

- NEUE HERBOLD recycling mill

- Mineral mill

- NEUE HERBOLD dry milling mill

- Powder grinding mill

- Metal mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.