- Production Machines

- Other Manufacturing Equipment

- Rotor mill

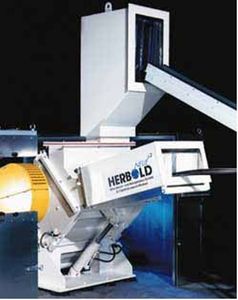

- NEUE HERBOLD Maschinen-u. Anlagenbau GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

Cutting mill SM serieshorizontalfor bottlesfor cables

Add to favorites

Compare this product

Characteristics

- Technology

- cutting

- Orientation

- horizontal

- Product applications

- for cables, chip, for plastics, for rubber, copper, for aluminum, for bottles

- Other characteristics

- dry milling, wet grinding, heavy-duty, heavy-duty

- Sector

- for recycling, for the chemical industry, for the plastics industry, for pipes and profiles, for thermoforming lines, for blow molding

- Output

Min.: 150 kg/h

(331 lb/h)Max.: 8,000 kg/h

(17,637 lb/h)- Motor power

Min.: 11 kW

(14.96 hp)Max.: 250 kW

(339.91 hp)- Machine weight

Min.: 1,000 kg

(2,205 lb)Max.: 12,000 kg

(26,455 lb)

Description

NEUE HERBOLD SM series granulators are specially designed for all universal types of applications.

- the size reduction of massive start-up lumps

- the size reduction of massive purgings

- the size reduction of massive profiles

- size reduction of general plastic scrap with extremely wall thicknesses.

- size reduction of voluminous hollow parts such as containers and crates.

The SM series is designed for versatile use and considered a all round granulator for todays recycler.

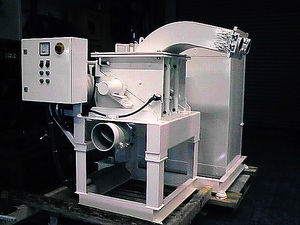

SM series granulators are designed with rotor and stator knives that are counter angled to each other producing a true scissors type cutting action. This design results in a cleaner more uniform granulate and reduced heat build up in the granulate. Double angle cut also reduces noise emissions and energy consumption. All knives are straight sharpening and require no special knife sharpening fixture. All cutting knives are pre-adjusted to the proper size gap outside the granulator with the use of the knife setting fixture which creates a constant gap between rotor blade circumference and screen resulting in reduced friction and therefore less thermal stress of the material. Knife changes can be accomplished 60% quicker and safer then adjusting knives within the granulator.

Advantages

- universal application useage

- reduced space requirement due to compact design

- energy-saving size reduction

- low noise level due to double-cross cutting knife configuration

- easy cleaning due to clam shell opening" characteristics

- higher through put rates

- reduced down time for rotor and stator knife replacement due

to pre-adjusted knives

Other NEUE HERBOLD Maschinen-u. Anlagenbau GmbH products

Granulators

Related Searches

- NEUE HERBOLD mill

- Screening unit

- Bulk material screening unit

- Horizontal grinding mill

- Vertical grinding mill

- Food lump breaker

- NEUE HERBOLD rotor mill

- Vibrating sieving machine

- Impact grinding mill

- Waste lump breaker

- Recycling screening unit

- NEUE HERBOLD knife mill

- NEUE HERBOLD plastic mill

- Hammer grinding mill

- Mill for the pharmaceutical industry

- NEUE HERBOLD recycling mill

- Mineral mill

- Powder grinding mill

- NEUE HERBOLD dry milling mill

- Metal mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.