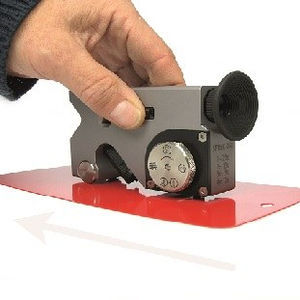

Portable thickness gauge MX seriesmetalsteelglass

Add to favorites

Compare this product

Characteristics

- Type

- portable

- Applications

- metal, steel, glass, plastic

- Technology

- ultrasonic

- Calibration

- automatic calibration

- Other characteristics

- precision, with data logger

- Measuring range

Max.: 500 mm

(19.69 in)Min.: 1 mm

(0.04 in)- Resolution

0 mm

(0 in)- Weight

295 g

(10.4 oz)

Description

The Ultrasonic Measuring Technique is used to measure the thickness of steel and all other metals, glass and homogenous plastics and to detect material flaws, corrosion and pits. The main advantage of ultrasonic measurement over traditional methods is that ultrasonic measurement can be performed with access to only one side of the material being measured. The ultrasonic gauges are used in the automotive, aircraft, machine and tool industry and especially to check the residual thickness of tanks and tubes.

The Ultrasonic Measuring Technique is used to measure the thickness of steel and all other metals, glass and homogenous plastics and to detect material flaws, corrosion and pits.

The main advantage of ultrasonic measurement over traditional methods is that ultrasonic measurement can be performed with access to only one side of the material being measured. The ultrasonic gauges are used in the automotive, aircraft, machine and tool industry and especially to check the residual thickness of tanks and tubes.

Serie MX

measure the thickness of materials from 1 mm and detect material flaws :

The devices MX-2, MX-3 and MX-5DL work with dual-element (transmit and receive) transducers, which not only measure the thickness of materials from 1 mm (steel) but are as well suitable to detect material flaws (corrosion and pits). A wide selection of dual-element transducers for any material and different applications are available.

MX-2 is a fixed velocity gauge that requires no special training to operate. It contains eight velocities of common materials and 2 velocities that the user can set using a simple software program.

Catalogs

No catalogs are available for this product.

See all of NEURTEK‘s catalogsRelated Searches

- Measuring device

- Indentation hardness tester

- Portable testing system

- Benchtop indentation hardness tester

- Digital hardness tester

- Digital measuring device

- Digital testing system

- Industrial testing system

- Portable measuring device

- Automatic testing system

- Industrial gauge

- Portable indentation hardness tester

- Temperature measuring device

- Benchtop measuring device

- Tester with LCD screen

- Resistance testing system

- Benchtop testing system

- Measuring device with display

- Laboratory measuring device

- Laboratory testing system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.