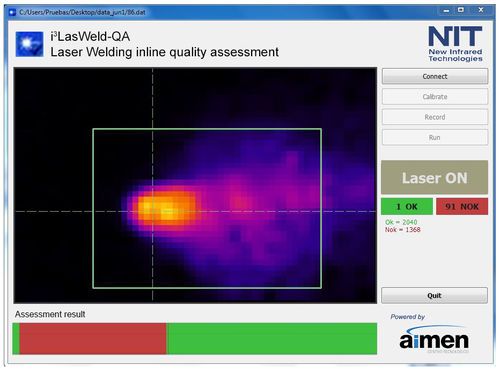

In line Infrared Imaging system for assessing in real time the quality of laser welding processes.

- The I3LASWELD system for the inline quality control of laser welding processes, capable of detecting defects in weld seams in real time and identifying defective parts.

- I3LASWELD provides high defects detection rates above 97%.

Defects:

- False friends

- Lack of penetration / lack of fusion

- Cracks, pores

- Underfilling

Main characteristics:

- Easy adapt to standard laser welding heads using C-mount optical interface

- The clasifier needs initial training

- Real-time defect detection during the welding process

- On-axis process observation using high-speed infrared imaging sensor (1 kHz)