- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

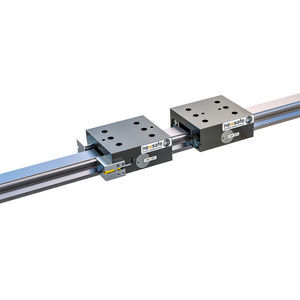

Disc brake BSB seriesmechanicalspringball screw

Add to favorites

Compare this product

Characteristics

- Type

- disc

- Operation

- spring, mechanical

- Other characteristics

- safety, high-torque, bi-directional, waterproof, compact, ball screw

- Torque

2 Nm, 8 Nm, 22 Nm, 45 Nm, 125 Nm

(1.4751 ft.lb, 5.9005 ft.lb, 16.2264 ft.lb, 33.1903 ft.lb, 92.1953 ft.lb)- Rotational speed

5,000 rpm, 10,000 rpm

(31,415.93 rad.min-1, 62,831.85 rad.min-1)

Description

Nexen’s Ball Screw Brake is a high-torque, spring-engaged brake acting on the machined end of a ball screw. It serves as a primary or redundant brake to prevent back driving if a power loss or mechanical defect occurs in the driveline.

The low backlash and coupling combination provides a high degree of accuracy for holding the ball screw position. An expanding shaft/clamping hub coupling connects the brake shaft to the end of the ball screw. The required coupling comes with an elastomer insert with high torsional stiffness.

Selection

Nexen offers an off-the-shelf braking solution for any ball screw application. These spring-engaged, air-released brakes eliminate the performance problems associated with electrical brakes for consistent, long-lasting performance.

Ball Screw Brakes provide reliable holding in a compact package

During a power loss, the motor has no holding torque allowing the ball screw to back drive and the load to drop. Ball screw brakes connect to the machined end of the ball screw to prevent back driving, load drops, and equipment damage during a power loss. Holding force up to 125 Nm (1100 in-lbs.)

Nexen's Ball Screw Brake Features

Low backlash for precision holding

Spring engaged, air released

Low inertia

High torsional rigidity

Bi-directional braking

Fast engagement

Meets IP67 dust and waterproof standards

Operates in vertical and horizontal applications

Allows for thermal expansion of ball screw

Ball Screw Applications

Nexen's Ball Screw Brakes are ideal for automated:

Robotics

Material handling systems

Custom lifts

Work platforms

Dust and waterproof conditions that need IP67

Machining centers

Catalogs

LINEAR MOTION CONTROL

4 Pages

Related Searches

- Clamp

- Coaxial gearbox

- Precision gearbox

- Compact gearbox

- Friction brake

- Solid-shaft gearbox

- Industrial gear reducer

- Spring brake

- Disc brake

- Electromagnetic brake

- Flange gearbox

- Friction clutch

- Friction brake caliper

- High load capacity gear reducer

- Spring brake caliper

- Gear rack

- Overload clutch

- Safety brake

- Flange-mounted gearbox

- Machine gear reducer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.