- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

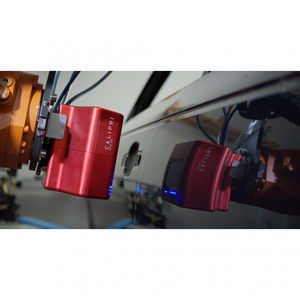

Multi-camera inspection system CB20opticallaser triangulationrobotic

Add to favorites

Compare this product

Characteristics

- Technology

- multi-camera, optical, laser triangulation

- Operational mode

- robotic

- Type

- for flush measurement, for gap measurement

- Applications

- for the automotive industry

- Configuration

- in-line

Description

COMPARABLE MEASURED DATA ENABLES CONCLUSIONS

• - Extreme versatility and independence of material surfaces

• - Cross-process evaluation strategies

• - Automated 100% inspection

• - Precision and reliability

The new CALIPRI CB20 is used for the challenging demands in final assembly. The revolutionary CaliBreeze technology enables optical measurements on every surface and combines the newly invented CaliBreeze technology with the proven CALIPRI principle. In order to optimize the naturally poor reflectivity of transparent and semi-transparent surfaces, the patented CaliBreeze technology produces optical contrast by applying an ultra-thin layer of condensed water on the measurement object. Thus, enhancing the optical properties of any surface, making measurements at highest precision and speed possible. After serving its purpose, the layer disappears within seconds without leaving any residue on the measurement object.

For less tricky measurement conditions like body-in-white or paintshop, we also have the CALIPRI C12 in our range. Calipri CB20- and C12-systems can be applied to any type of robot. In case using cobots, the Calipri system can evaluate gaps directly next to the workers of the assembly line without any barriers. All Calipri systems automatically compensate tilt and roll of the sensor and reproducible return the real gap value. Thanks to cross-system inspection plans and evaluation methods, you can easily roll out measurement plans for new model lines company-wide and compare the measurement results of individual stations.

Catalogs

No catalogs are available for this product.

See all of NEXTSENSE GmbH‘s catalogsRelated Searches

- Inspection system

- Automated inspection system

- Camera inspection system

- Measurement inspection system

- Optical inspection system

- In-line inspection system

- Inspection system for the automotive industry

- Handheld inspection system

- Manual inspection system

- 2D inspection system

- Laser inspection system

- NDT inspection system

- Inspection system for the metallurgical industry

- Rugged inspection system

- Metal inspection system

- Multi-camera inspection system

- Robotic inspection system

- Geometry inspection system

- Gap measurement inspection system

- Flush measurement inspection system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.