- Packing - Handling - Logistics

- Packing and Packaging

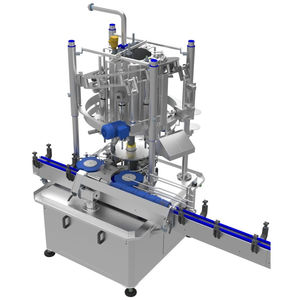

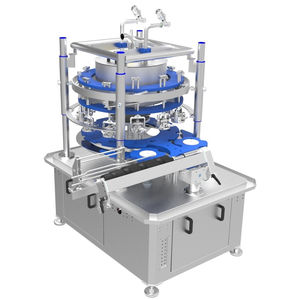

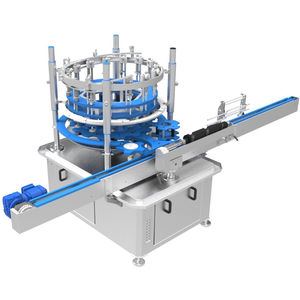

- Automatic filling machine

- NIKO Nahrungsmittel-Maschinen GmbH & Co. KG

Automatic filler Typ_055containerliquidsfor pasty products

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- container

- Product applications

- liquids, for pasty products

- Domain

- for the food industry

- Type

- piston, in-line, auger

- Other characteristics

- sterile

- Volume

25 l

(6.6 gal)

Description

The Inline filler was designed for small to medium capacities. Since the volume is limited in a conventional piston filler, it is possible with this filler to fill from very small containers up to 25 liter containers. Whether liquid, pasty or products with chunky proportions, with this filler is a wide range fillable.

• 4 -16 filling stations, single or double track.

• Measurement Magnetic-Inductive (MID) or mass meter (Coriolis), Cleaning in Place (CIP).

The machine completely consists of Cr-Ni-steel 1.4301 / 1.4404 (AISI 304/316) or any other stainless material, such as plastics, with the exception of drive and bearing components.

• Servo axes for precise positioning

• Auger or stopper system

• Heated valves, hoses, flow meters and product tanks

• sterile air in the filling room (laminar flow)

• Real-time correction of filling

• Over or under mirror filling

VIDEO

Catalogs

No catalogs are available for this product.

See all of NIKO Nahrungsmittel-Maschinen GmbH & Co. KG‘s catalogsOther NIKO Nahrungsmittel-Maschinen GmbH & Co. KG products

Filling Machines

Related Searches

- Automatic filler

- Liquid filler

- Filler for the food industry

- Food product filling machine

- Volumetric filler

- Container filler

- Piston filler

- Can filler

- Linear filler

- Rotary filler

- Filler with conveyor

- Auger filling machine

- Depalletizer

- Jar filler

- Pasty product filler

- Automatic depalletizer

- Palletising system

- Aseptic filling system

- Palletizer and depalletizer

- Glass container filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.