- Industrial machines and equipment

- Heat Exchanger and Refrigeration

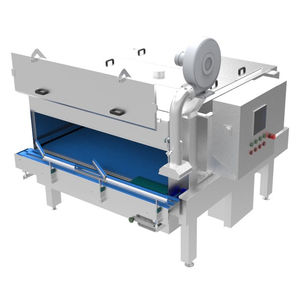

- Water cooler

- NIKO Nahrungsmittel-Maschinen GmbH & Co. KG

Water cooler Typ_091ice waterfor the food industrystainless steel

Add to favorites

Compare this product

Characteristics

- Material

- water, ice water

- Applications

- for the food industry

- Other characteristics

- stainless steel, high-performance, active, passive

Description

Operation takes place continuously on conveyor belts of different designs, adapted to the container shapes and dimensions to be processed.

To cool the containers, water (eg well water or ice water) is circulated countercurrently to the product stream and sprayed over the products with pumps and nozzle sticks. For heat recovery and the associated increased energy efficiency, use of intermediate heat exchangers is advantageous. The associated separation of the cooling circuit in the primary and secondary circuit usually leads to longer service life due to reduced dirt entry.

• Machine design in Cr-Ni steel 1.4301 (AISI 304)

• Tailor-made sizes, tailored to the performance and circumstances of the customer

• Version with passive or active holding line for headspace pasteurization possible

Catalogs

No catalogs are available for this product.

See all of NIKO Nahrungsmittel-Maschinen GmbH & Co. KG‘s catalogsOther NIKO Nahrungsmittel-Maschinen GmbH & Co. KG products

Tunnel- / Pasteurizers / Coolers / Heater

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.