- Products

- Catalogs

- News & Trends

- Exhibitions

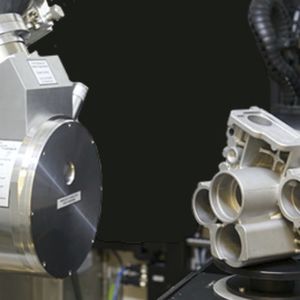

X-ray inspection system VOXLS 40 C 450scanningCTautomatic

Add to favorites

Compare this product

Characteristics

- Technology

- X-ray, scanning, CT

- Operational mode

- automatic

- Applications

- for production, for the automotive industry, for the aerospace industry

- Product applications

- for large parts

- Other characteristics

- fast, computer-controlled

Description

Nikon’s versatile, large-envelope X-ray and CT systems can inspect items of diverse size and density, internally and externally, enabling them to perform virtually limitless tasks within industry, inspection bureaux and academia.

A multitude of configuration options to meet your exact inspection requirements

Nikon’s large-envelope system range combines metrology grade, granite-based manipulator construction with a large scanning volume, multi-source flexibility, dual detector functionality and an extensive range of CT acquisition modes, enabling them to excel in any inspection environment, from R&D labs to the shop floor.

Highly Configurable Line-up

With 8 different X-ray sources, 7 detectors, 3 granite base lengths and 2 manipulator constructions to choose from, housed in either a single-piece cabinet, panelised room or pre-existing shielded enclosure, you’ll find a system configuration to match your requirements.

Multi-source Functionality

Select up to 3 X-ray sources from Nikon’s extensive microfocus range to ensure you have the optimum combination of penetrative power, resolution and scan speed for all your applications.

Dual Detector Flexibility

A choice of industry-leading, flat panel detectors with small pixel sizes and fast exposures, combined with Nikon’s unique CLDA, enables high-throughput CT and DR for all part types, plus advanced scatter correction for high-density parts.

Metrology Grade Manipulator

Our granite-based manipulators are combined with rigid towers and precision motors and encoders. The resulting construction ensures superior mechanical and thermal stability, leading to enhanced positional accuracy and repeatability.

VIDEO

Catalogs

VOXLS 30 SERIES

15 Pages

Related Searches

- Digital camera module

- Visible camera system

- CMOS camera module

- Industrial camera system

- Full-color camera system

- USB camera module

- Compact imager

- Monochrome camera module

- High-definition camera

- Inspection system

- High-speed camera system

- High-performance camera module

- Laboratory imager

- Megapixel camera system

- Inspection machine

- High-sensitivity imager

- Automated inspection system

- Full HD camera module

- Measuring camera system

- Low light camera

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.