- Products

- Catalogs

- News & Trends

- Exhibitions

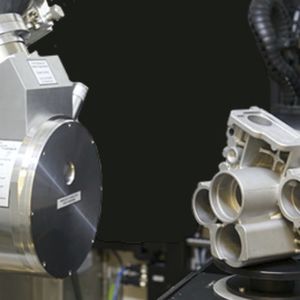

X-ray inspection machine VOXLS 30 C series CTsurfacefor the electronics industry

Add to favorites

Compare this product

Characteristics

- Technology

- X-ray, CT

- Applications

- surface

- Sector

- for the electronics industry, for the automotive industry, medical, for the aerospace industry

- Other characteristics

- automated

Description

Nikon’s VOXLS 30 Series systems deliver automation readiness, packaged in an efficient footprint and paired with scan energies of 225 kV, 320 kV or 450 kV, making it an ideal solution for small-to-mid-sized samples of low-to-high density.

Production automation-ready with autoloading and robotic integration capabilities available

Next level X-ray CT

The VOXLS 30 Series of X-ray and CT systems is equally at home in the R&D laboratory as it is on the production line and can utilise automated robotics and industry 4.0 integrations. The system is built for repeatability and reliability through the metrology-grade, granite-based manipulator, and rigid steel towers.

Three Source Options

Nikon’s VOXLS 30 C 225, 30 C 320 and 30 C 450 models have maximum source energies of 225 kV, 320 kV and 450 kV respectively for examining parts of various densities and sizes. By offering a selection of thoughtfully designed sources, Nikon empowers manufacturers to configure the optimal inspection system for their quality control needs. The flexible 30 Series scales to meet current and future requirements across diverse industries and sample types.

Motorised FID

In traditional X-ray CT systems, the Focus to Imager Distance (FID) is either fixed or manually adjustable. However, the VOXLS 30 Series has motorised FID, allowing effortless adjustment of the distance between the X-ray source and detector with sub-millimetre precision. Reducing the FID provides dramatically greater X-ray photon flux, significantly faster scan times and increased signal-to-noise ratio for enhanced image quality.

Catalogs

No catalogs are available for this product.

See all of Nikon Metrology‘s catalogsRelated Searches

- Nikon Metrology measuring system

- Micrometer

- Optical measuring machine

- Nikon Metrology automatic measuring system

- Laser scanning system

- Inspection machine

- Measurement scanning system

- 3D scanning system

- Nikon Metrology high-precision measuring system

- Nikon Metrology measuring system for industrial applications

- Nikon Metrology parts measuring system

- Distance measuring machine

- Control measuring machine

- Non-contact measuring machine

- Diameter measuring machine

- Digital micrometer

- Nikon Metrology laser measuring system

- Nikon Metrology video measuring system

- Inspection scanning system

- High-resolution scanning system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.